How to rubberize dog agility contact equipment

EMMCO SPORT is an innovative manufacturer of dog agility equipment

1344

STEPS

TOOLS

Surface area to be rubberized needs to be clean and free of any dirt or grime. Use ammonia based cleaner and paper towels.

Then a very thin layer of binder is applied to the surface. Spread the binder with a trowel. Next weigh rubber granules and binder. The exact ratio of granules to binder is very important.

Spread the granules on the primed surface with a clean trowel. A form is being used to contain the rubber binder mixture.

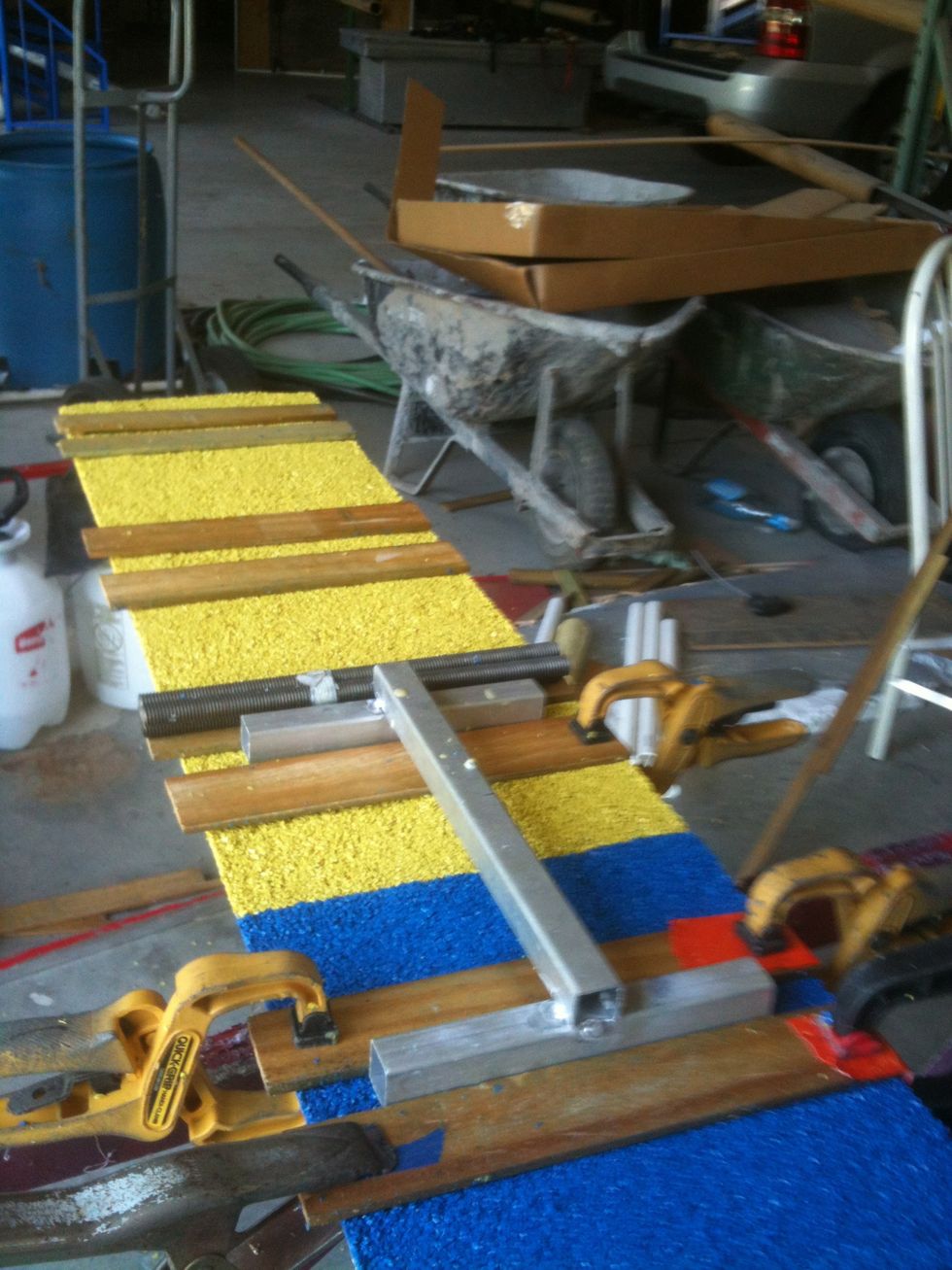

Adding blue rubber granule mixture to the center plank of a dog walk. Form wooden strips are clamped in place to contain granules.

The ascending and descending planks of the dog walk have contact zones. Here we are making the transition from blue to yellow prepared granules. Wooden forms must be removed promptly.

Close up of transition to new color granules for contact area on dog walk.

Important: The binder used in this process is moisture cured. If you are in a humid environment, the binder will cured more quickly and if your environment is very dry spray the surface with water.

Always remove forms before the rubber mixture is set and cured! It will be very difficult to remove forms once the mixture is cured. Just about impossible.

If slats are being added to the Dog Walk or A-frame, lay out the correct slat pattern for the appropriate sanctioning group.

Add binder to the surface area of the slat and then press the prepared granules into the form and square of the edges with a small pieces of wood.

Pressing granules into place and squaring off the edge.

Slats can be placed on the surface of a rubberized contact, but the most durable way to approach slats is to form the slats on the surface to start.

Yellow contact zone slats added first before rubberizing the entire surface area. Form is doubled to create appropriate slat thickness.

Slats prepared first on an A-Frame.

Completed A-Frame surface.

Completed Dog Walk planks. Always rubberize in a very well ventilated area!

For more information see: http://blogs.emmcosport.com/?p=22

- Rubber granules

- Binder

- Gallon size plastic bags

- Disposable plastic gloves

- Trowels

- Spatulas

- Mineral Spirits

- Heavy Duty Paper Towels

- Wooden Slats to create forms

- Clamps

- Scale for weighing granules and binder

- Sawhorses to support equipment

- Heavy duty tape

- Weights to hold slat forms down

- Ammonia based cleaner

The Conversation (0)

Sign Up