STEPS

TOOLS

Gather your supply's

Tadaaa!

Line up at least 2 sides of your glued up veneer to so you can get more rings or cleaner cuts later on.

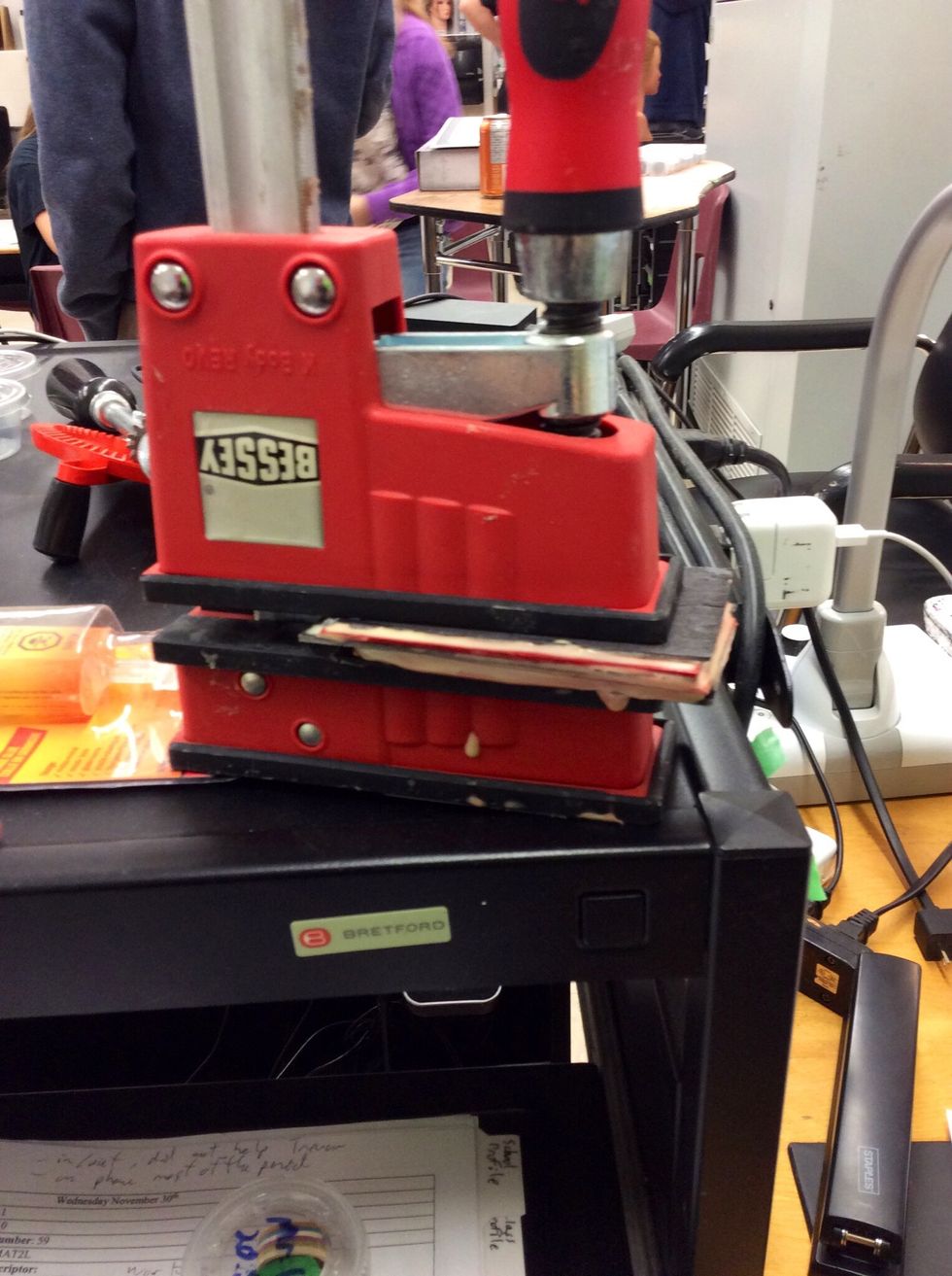

Put the glued up veneers into your clamp. having a friend hold the clamp open so you can hold the veneers while he clamps it.

Clamp it down.

Clean up.

Let sit for 24 hours. to ensure that the glue is fully dried.

Next day take glued up veneer out of the clamp.

Use a drill bit to cut a hole sized to your finger you want.

Find the fitting cutting jig for your ring

Put ring in jig and clamp it down to a table

Your setup should look something like this

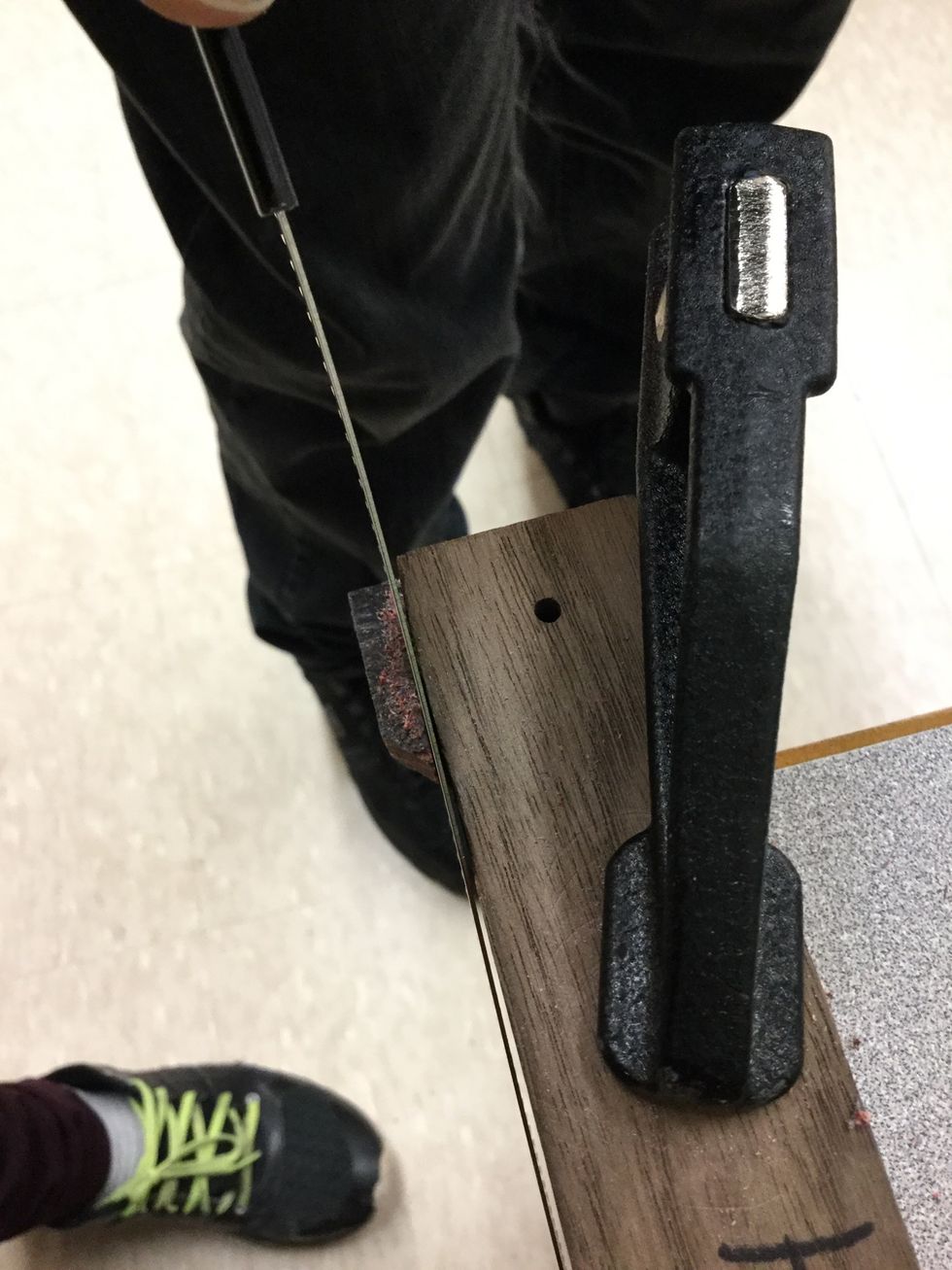

Now take a flush cut saw and use the side of the jig to get a even cut

Make sure your saw is flush with the jig and ring

Now that the first cut is done adjust the ring around so you have more wood to cut

Once you have cut and adjusted a couple of times you should end up with something like this.

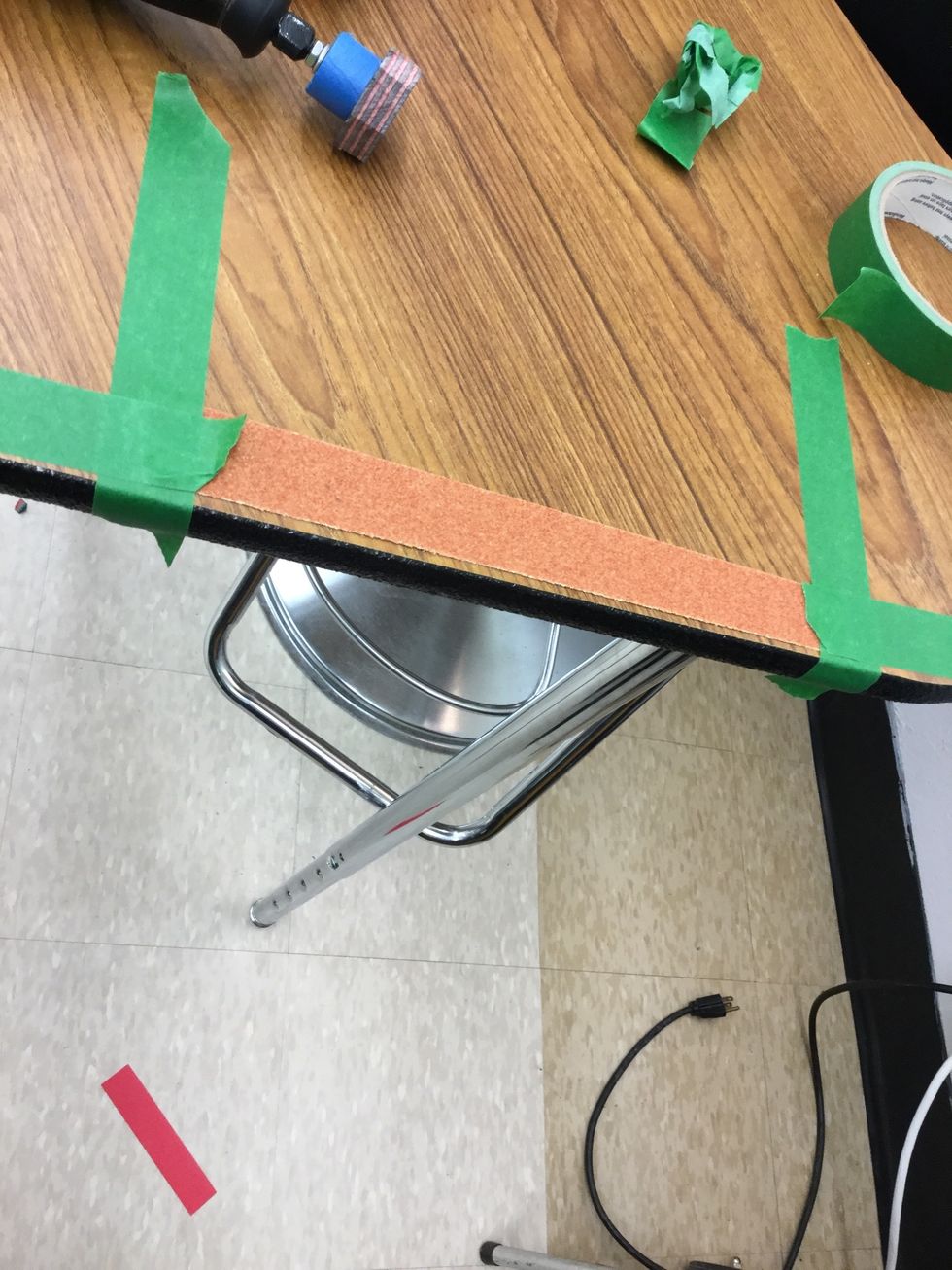

Tape a piece of 80 grit sand paper to the table

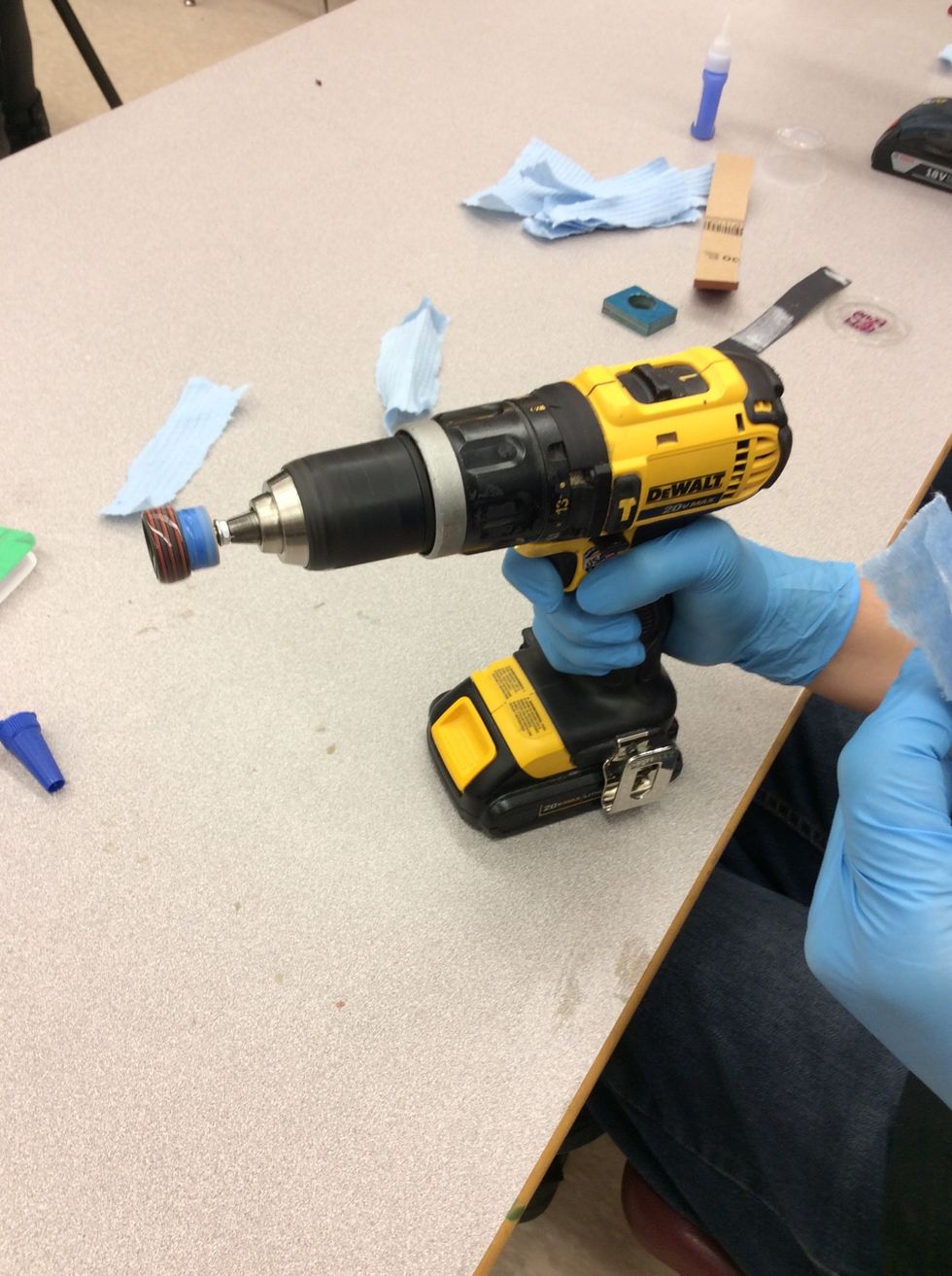

Attract the fitting bit and the ring on to the Dremel or drill

Now start to sand the ring until thin and round

Once roughly sanded and rounded it should look something like this

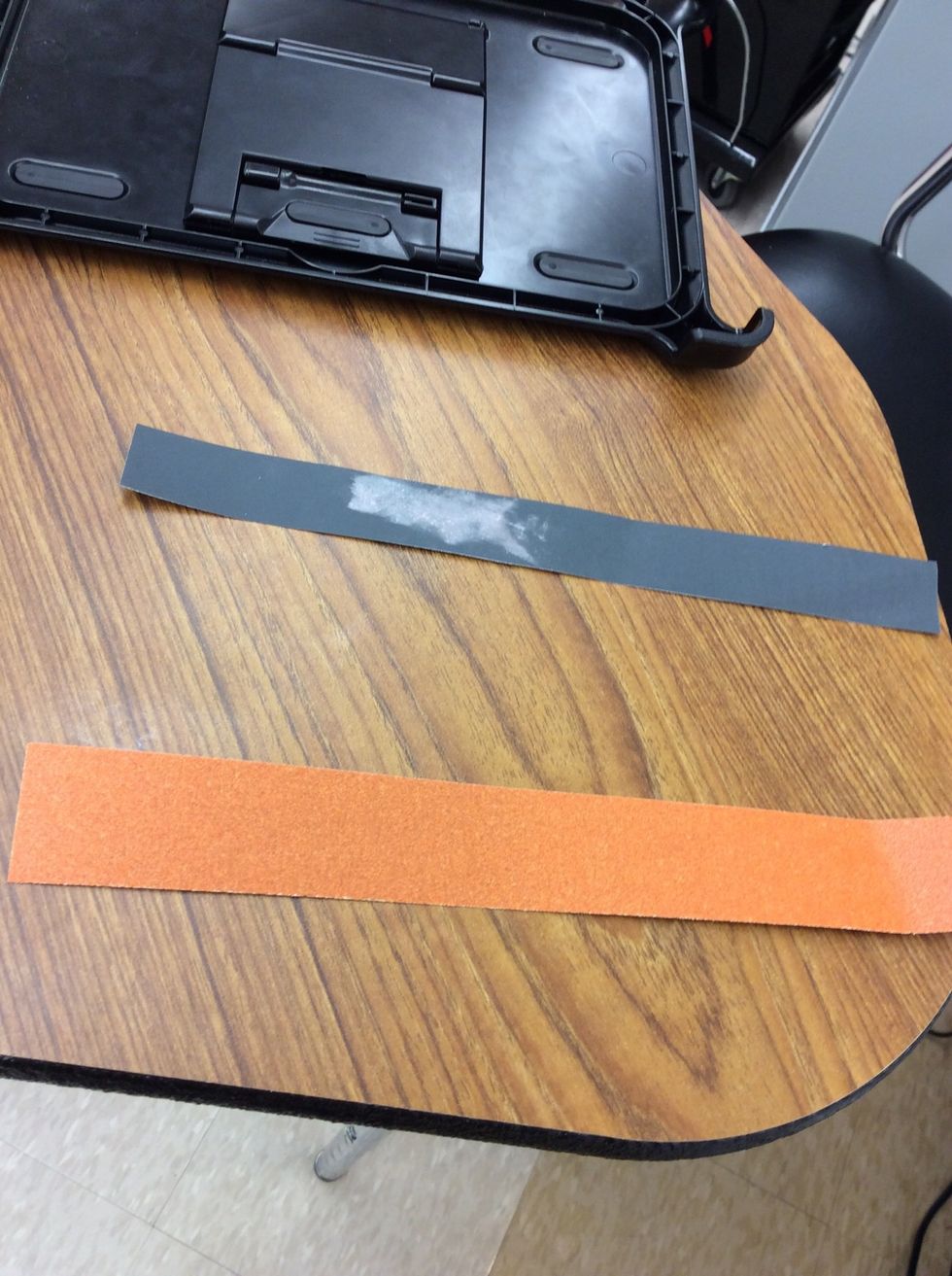

Now get a piece of 220 and 400 grit sandpaper

Start sanding with the 220 making sure to round the edges

Once rounded on edges take the 400 grit and run it around the ring to make it really smooth

Now take the 220 and start to hand sand the inside smoothing it and curving he edges in for a nicer more comfortable fit

When is all sanded and rounded it should look something like this

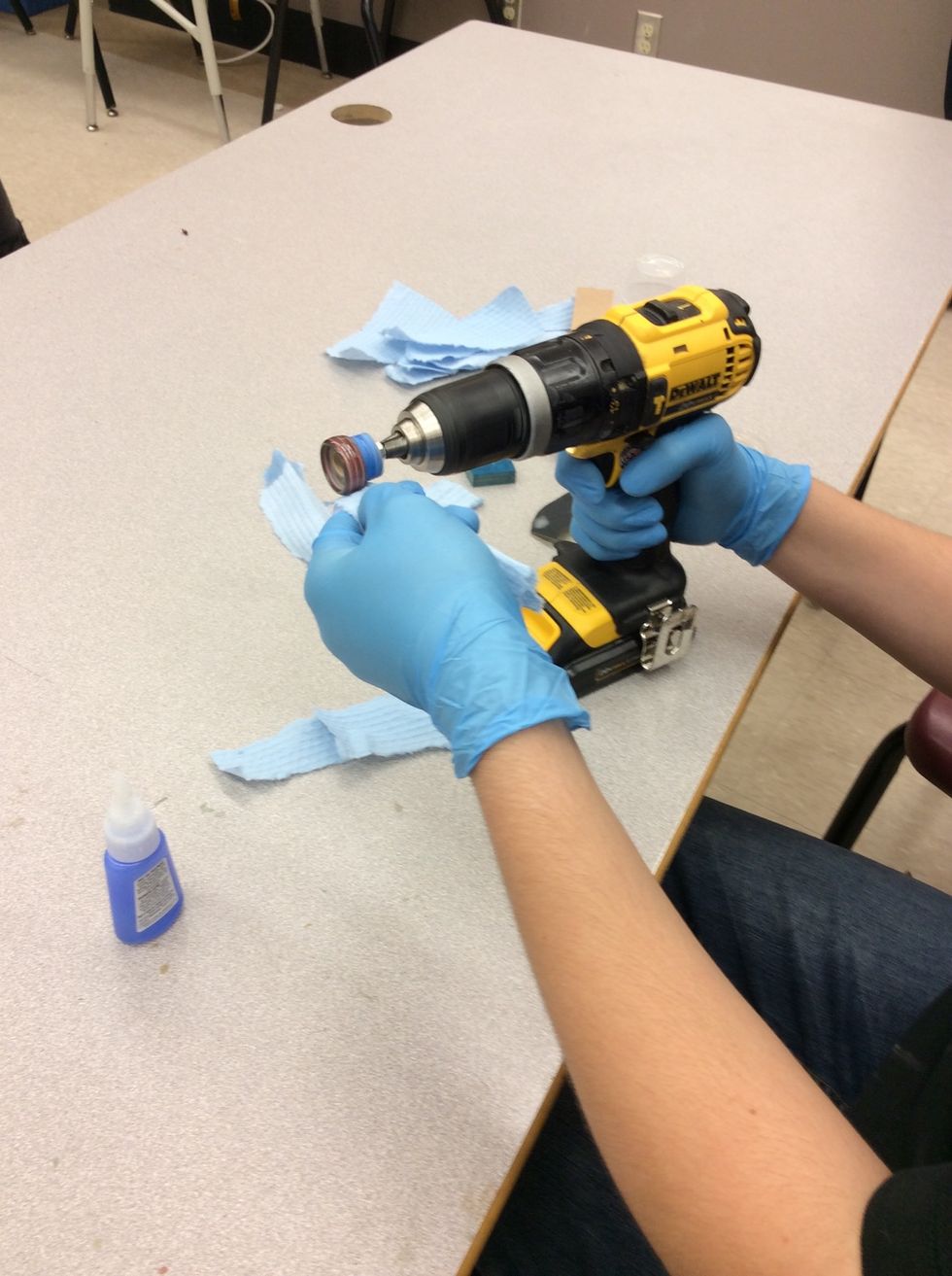

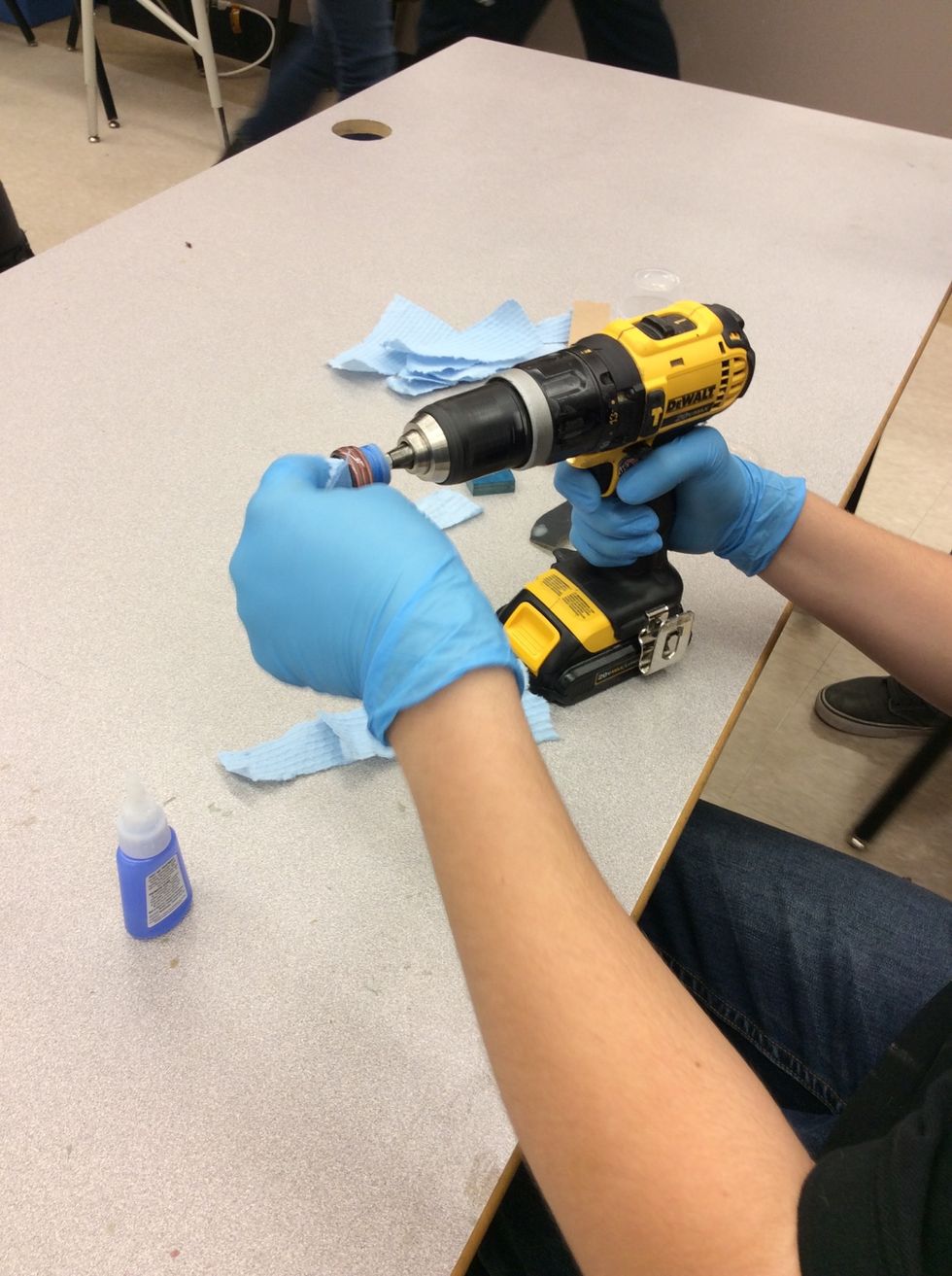

Now time to finish your ring! Take a industrial cloth and put a thick layer of super glue on the cloth. You are going to want 8 to 10 coats of glue

And put it onto the ring making sure you are slowly turning the drill

Do not apply to ring for longer then about 3 to 5 seconds. The glue will start to harden on the cloth scratching the ring. We don't want that.

Don't forget to coat the inside as well.

Dry between each coat

- 6.0 Veneers

- 1.0 Clamp

- 1.0 Titebond 3 glue

- 1.0 Drill or Dremel

- 1.0 A friend

- 1.0 Superglue

- 1.0 80 grit sandpaper

- 1.0 220 grit sandpaper

- 1.0 400 grit sandpaper

- 1.0 Flush cut saw

- 1.0 A cutting jig

- 5.0 Industrial cloth

- 1.0 Custom drill bit to fit ring

The Conversation (0)

Sign Up