STEPS

TOOLS

Gather your tools and supplies

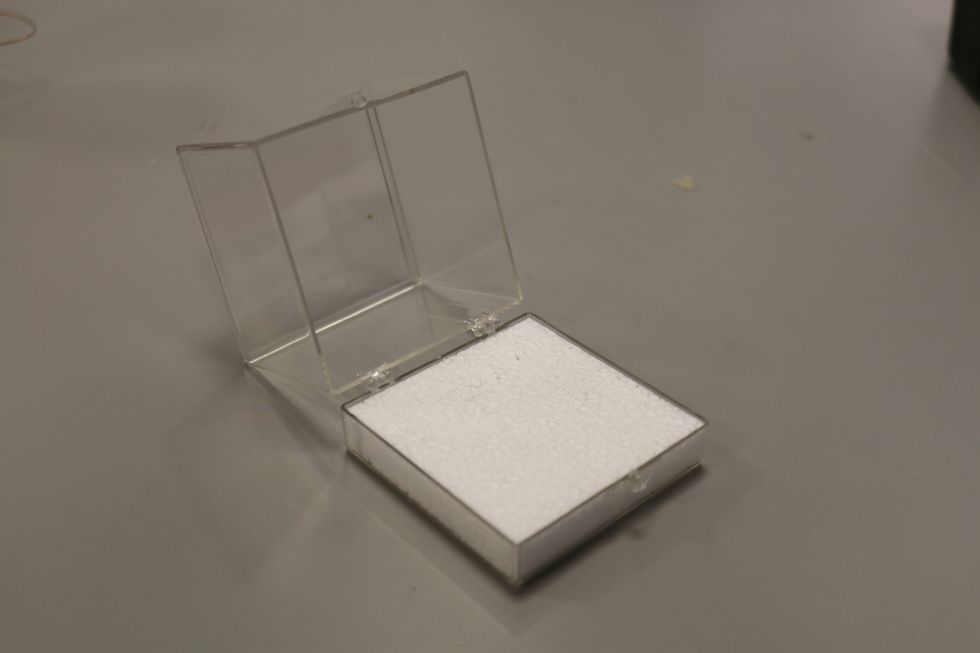

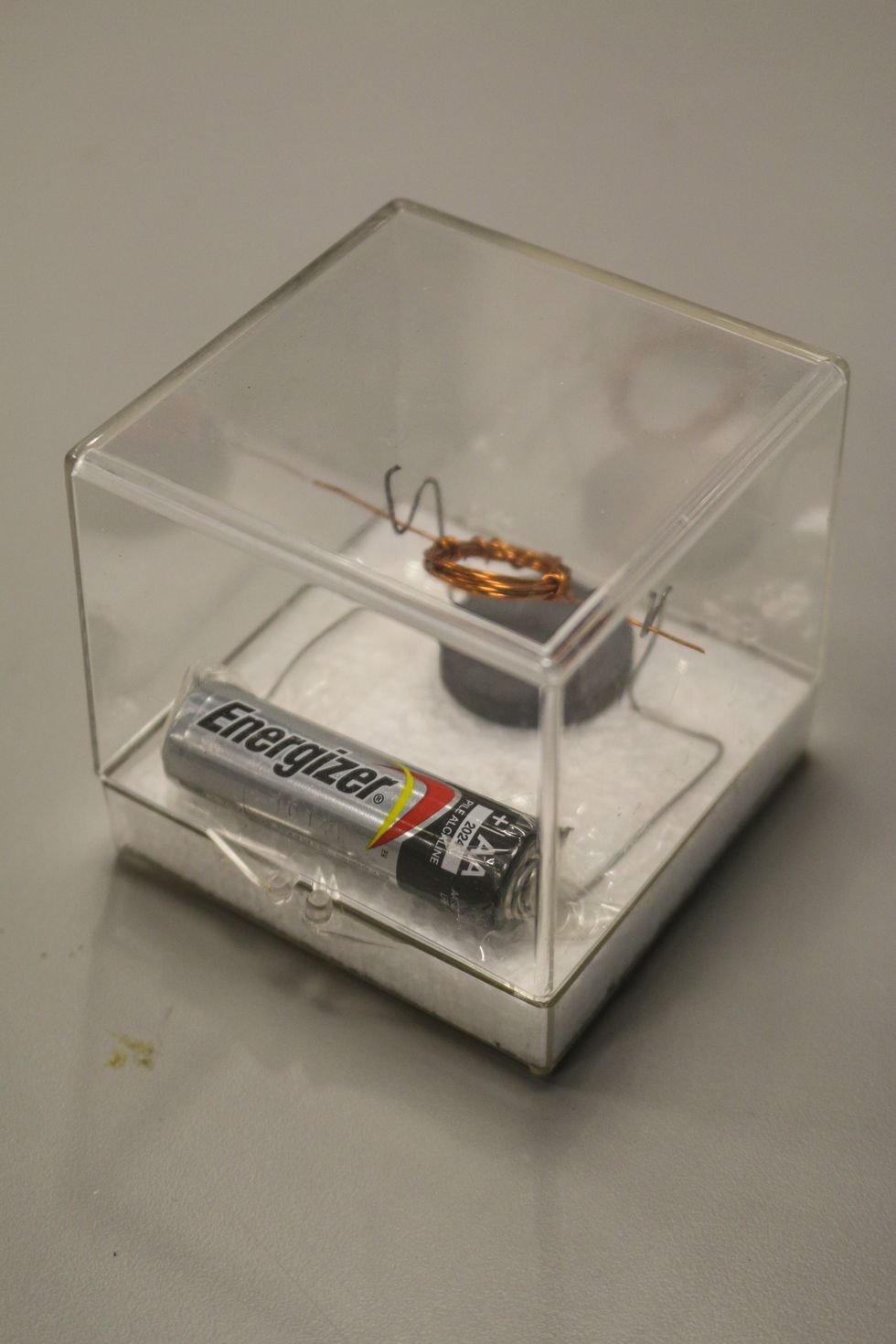

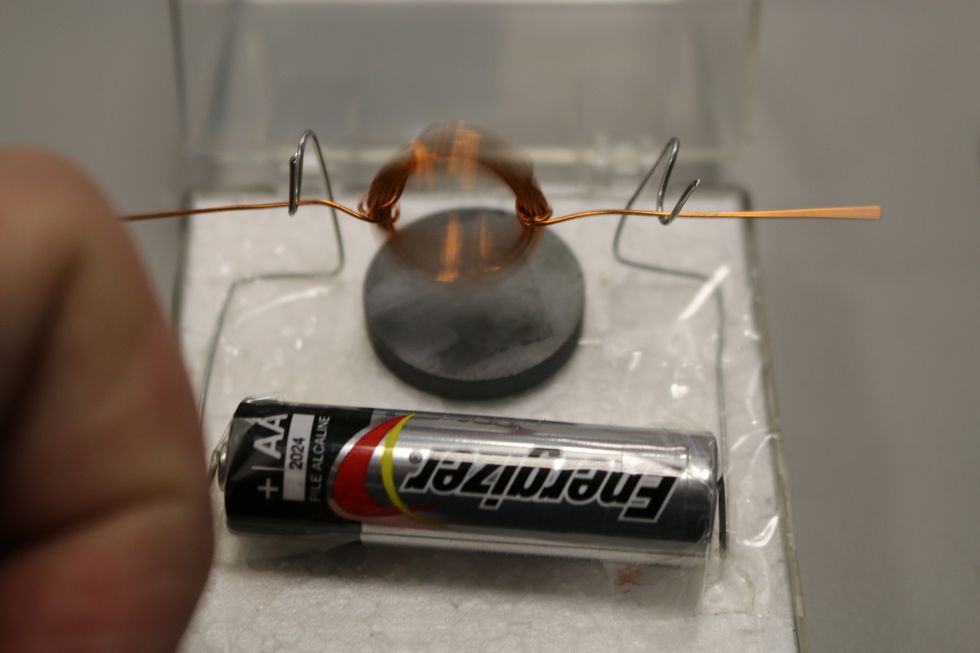

You'll want a block of styrofoam or wood to build your motor on. We were lucky to have plastic display boxes that worked well.

Your motor will be powered by one AA 1.5 volt motor!

We tried more expensive neodymium magnets, but found that disk magnets about the size of a nickle or quarter work just fine.

If you are doing a workshop its great to have a working example to help everyone see how to assemble the motor.

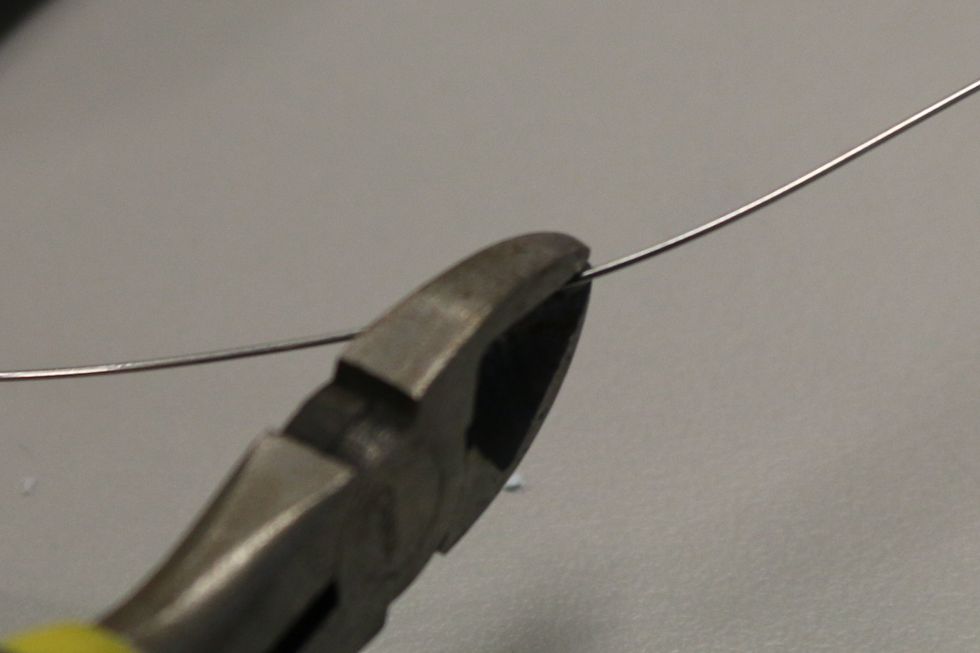

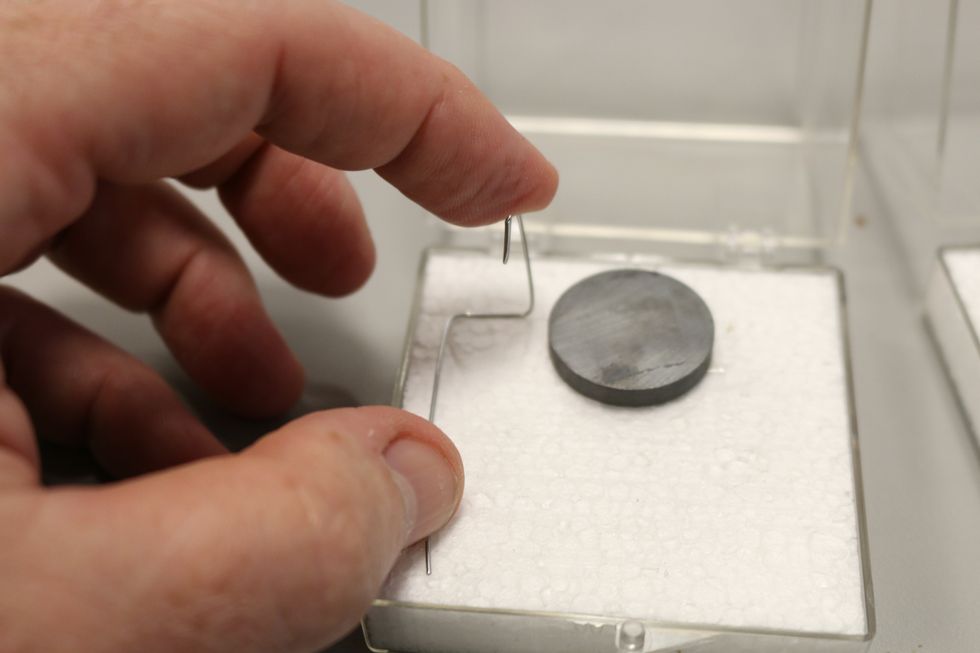

Lets get started - grab the steel wire. Cut a piece about 5" of the wire for one side of the armature (the structure that holds the copper coil).

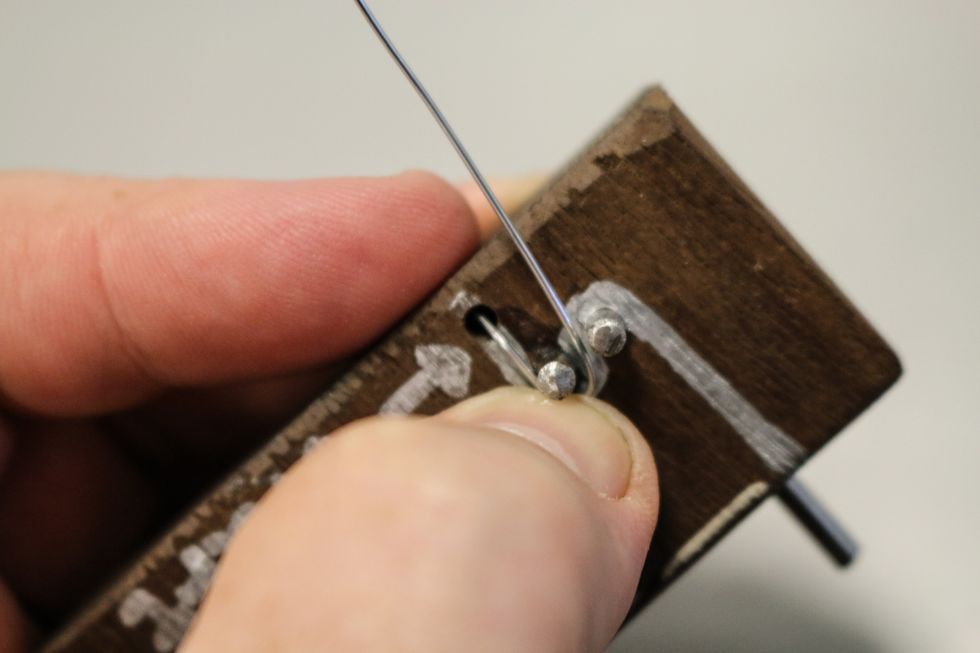

If using a jig (we'll post a how-to-make a jig soon to the end of this how to) start the wire by putting one end in the hole marked "start" on the "1" side.

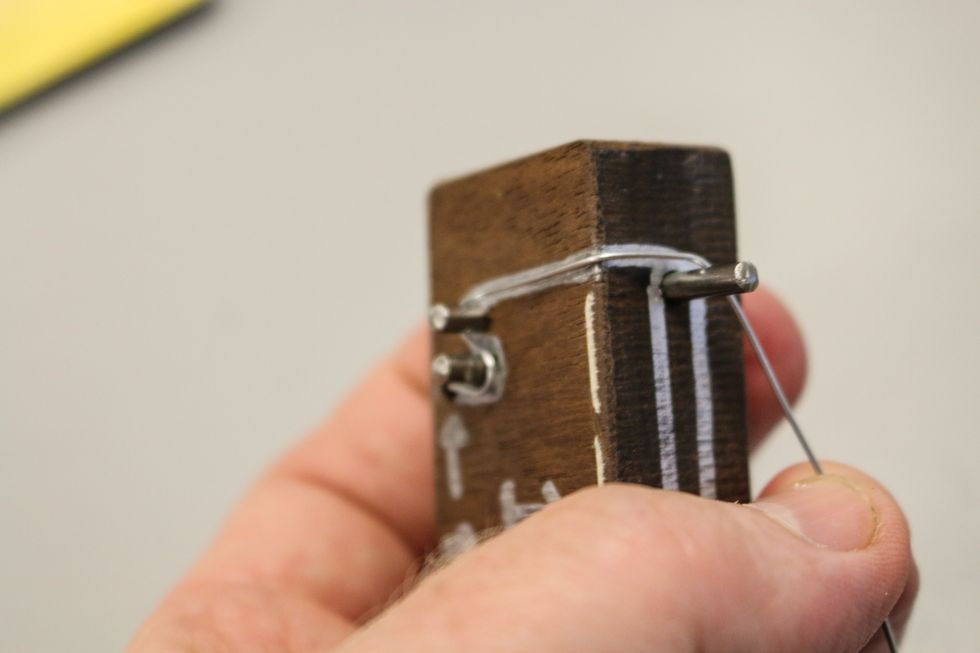

Following the direction line marked on the jig, hold down the starting end in the hole and start to bend the wire around the pins...

Keep following the line. Across each angle, try to bend the wire in sharp bends following the corners of the jig.

Continue bending. You can see in this image the wire wants to bend up. Press down tight against the pins and corners and it should keep its shape. You'll trim any excess wire when you come to the end.

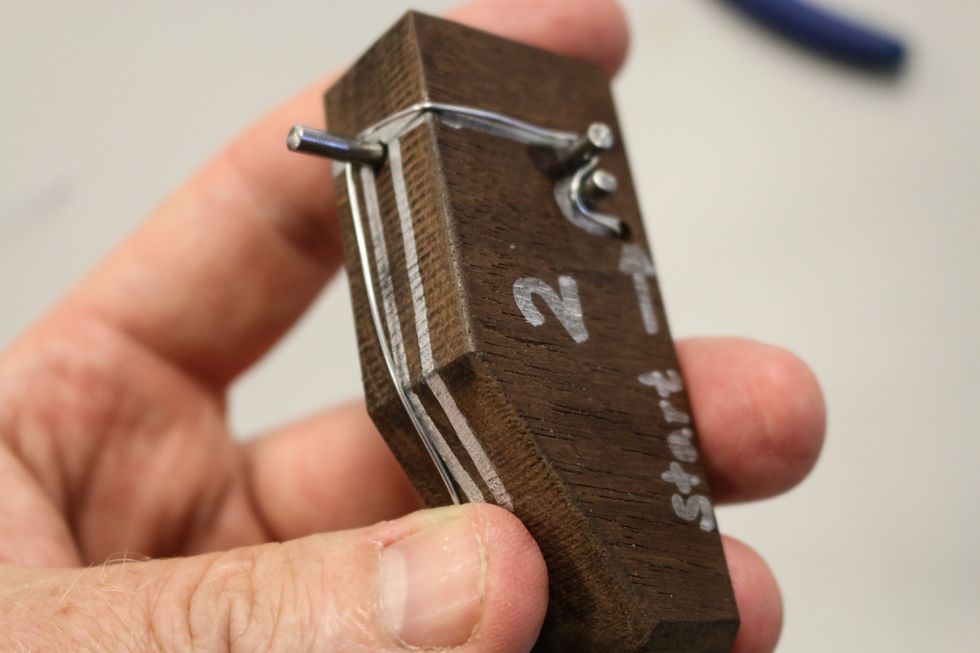

Now you can take it off the jig and bend the wire in sharper, straighter angles.

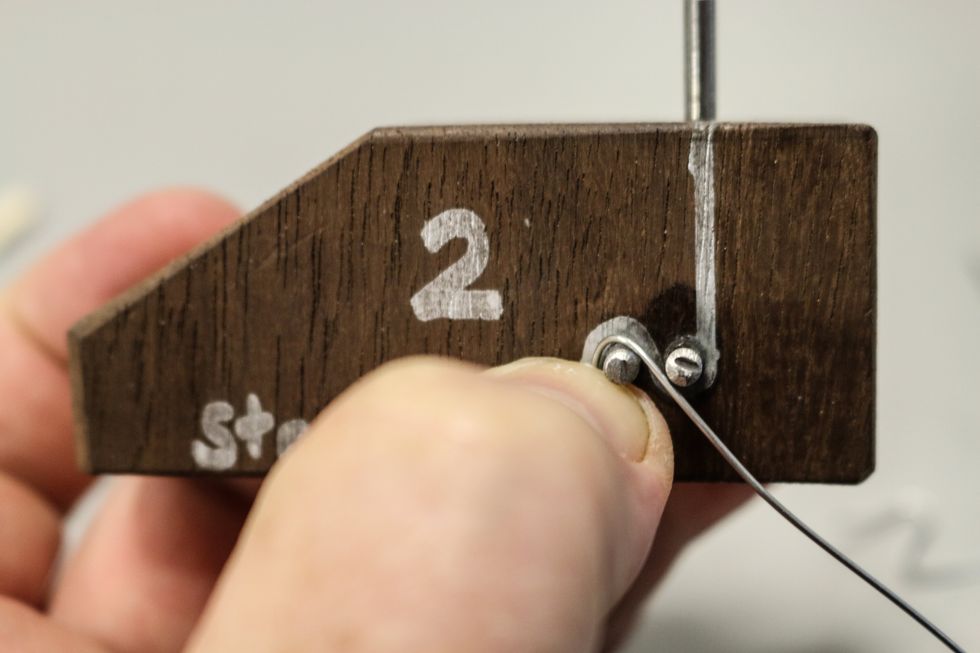

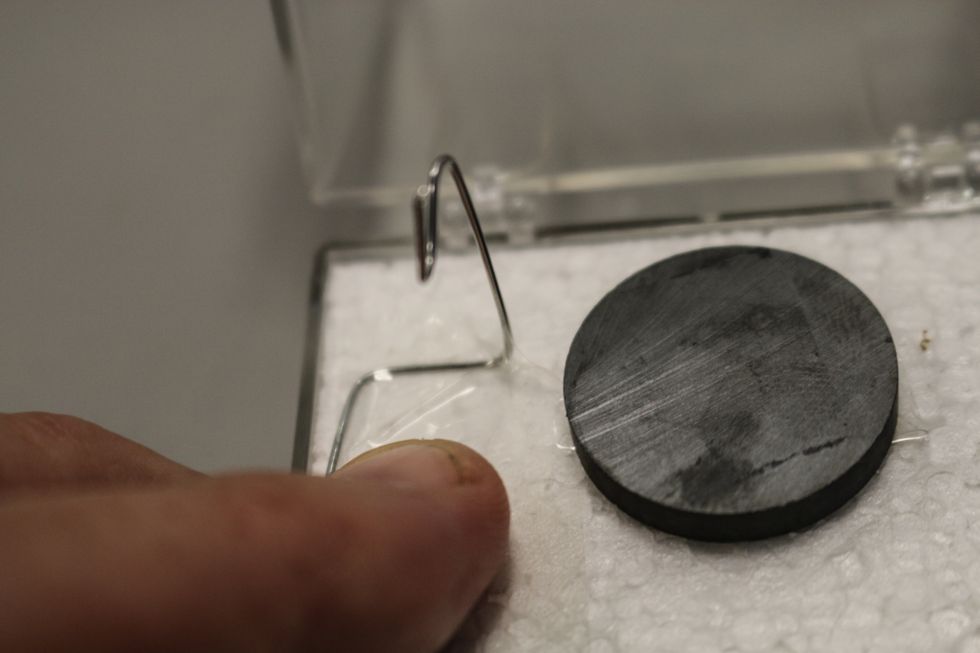

Start another piece of the steel wire on the opposite (side "2") of the jig. This wire will "mirror" the first wire.

You are following the same path just with opposite bends. Bend over the top and following the previous direction, trim extra wire off.

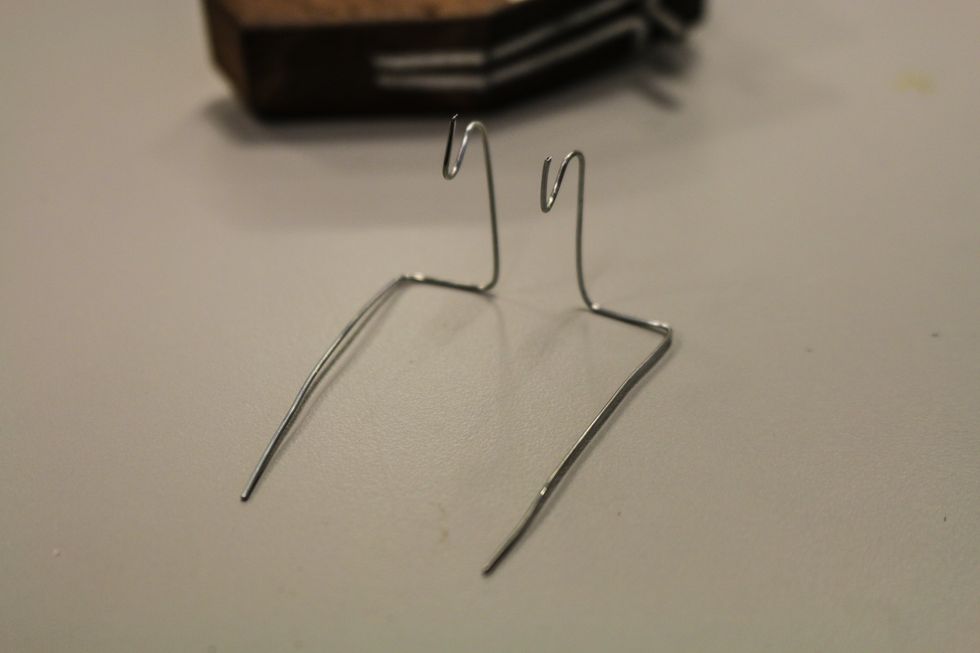

Taking off the second wire, sharpen the corners of the bends. You should be able to set them both down without tipping over. You can see where the hooks will hold the copper coil.

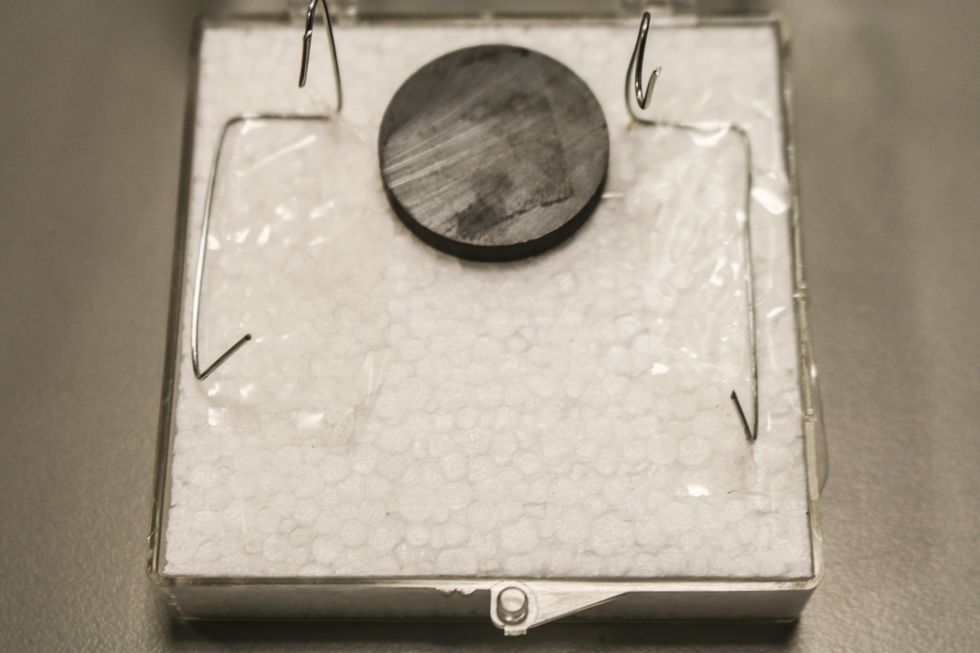

Now you'll be taping down your magnet in place.

Make a tape roll...

Press the sticky tape roll onto the magnet.

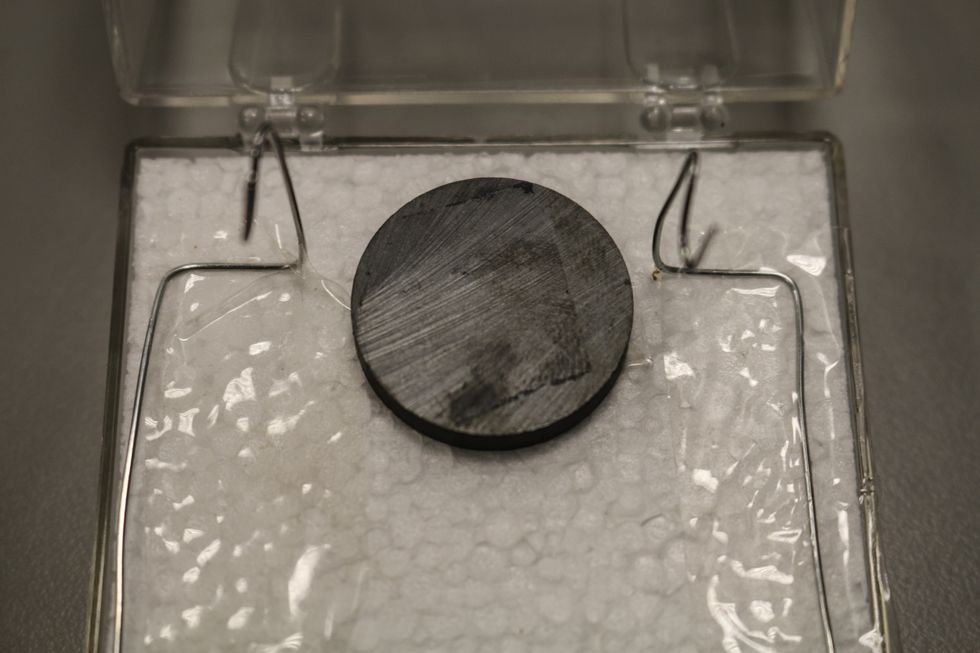

Looking at the example ( or these photos) position the magnet near one side of the block of foam, but in the center from the two sides.

Now take one of your bent wires and place it along one side of the magnet, center the hook so it follows an imaginary line through the center of the magnet. We want the hooks centered so the coil is.

Tape it down. Press the tape so the wire does not move.

Tape the other hook wire on the opposite side. Notice how they are lined up.

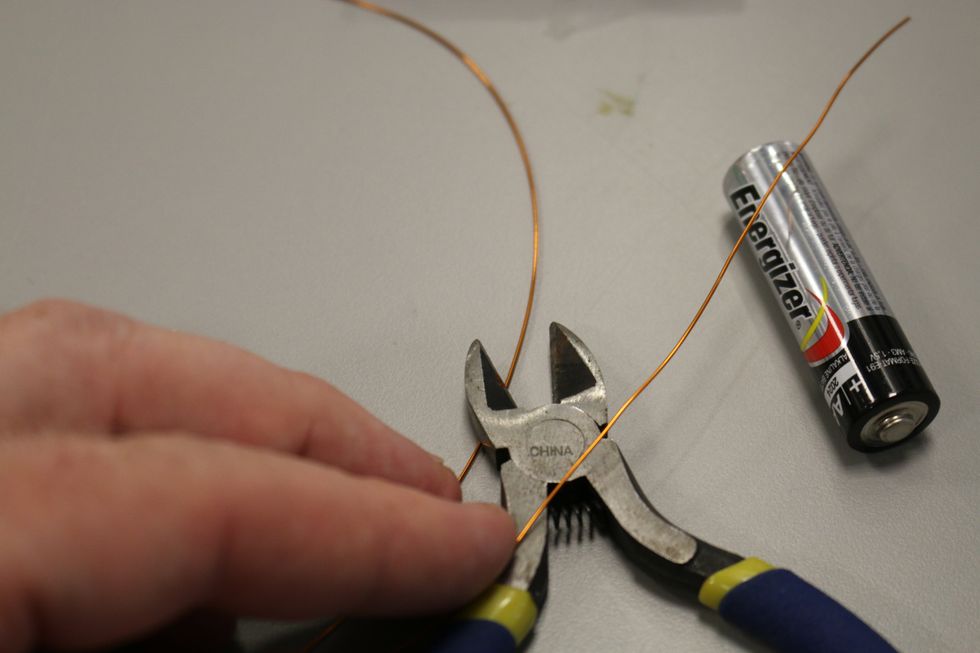

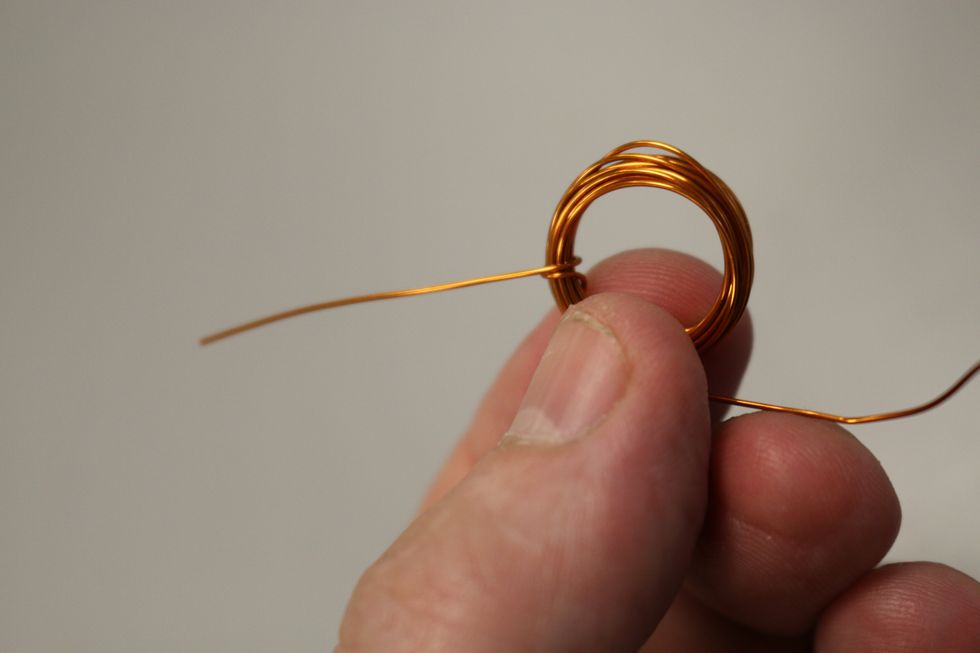

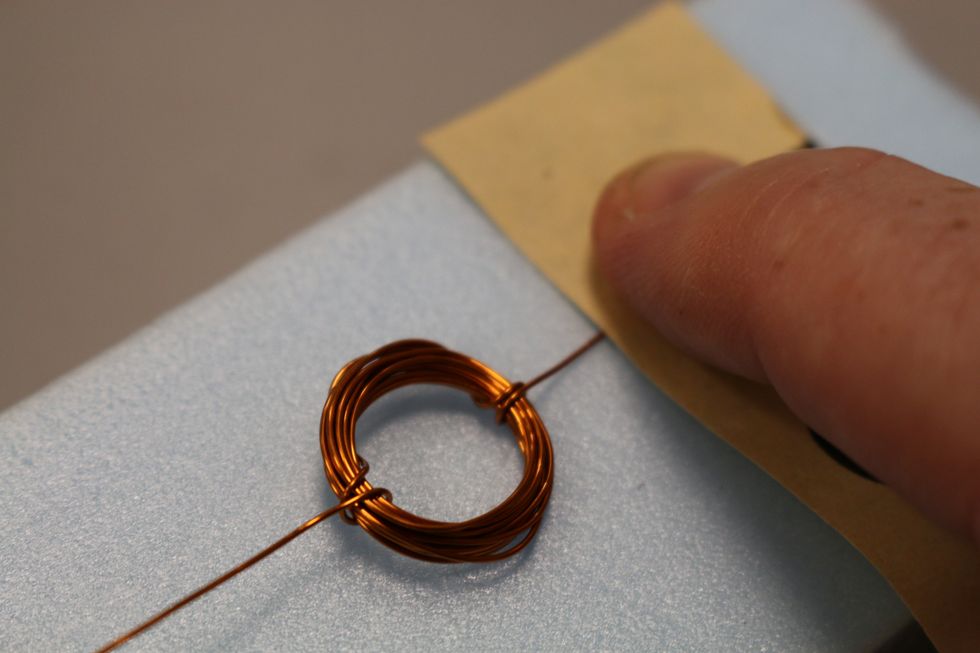

Next we need the copper wire. Cut an 18" piece.

You'll use your battery to wrap the coil. Have about 2" of wire sticking out from the battery and hold it down against the battery and start coiling it around the battery.

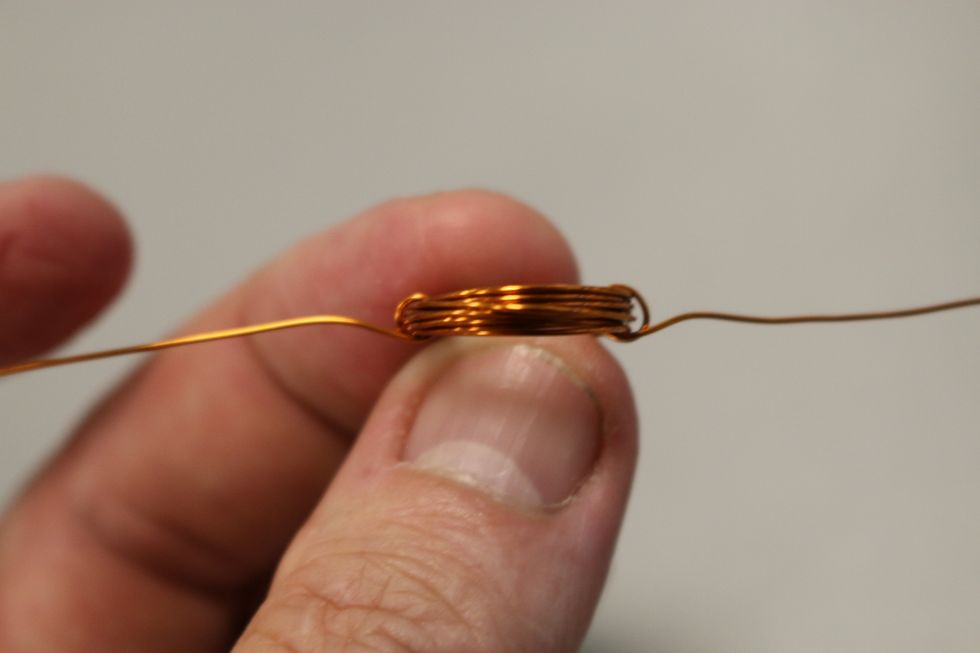

Coil it around until you have about 2" left.

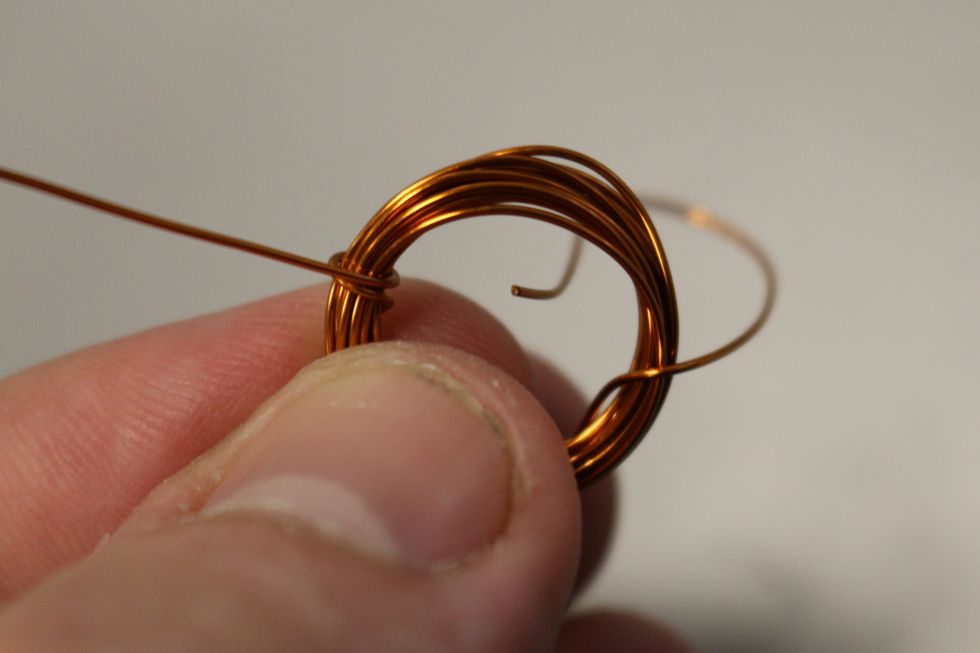

Slide it off the battery and then pull one end through the coil and wrap it around once to hold that end in place.

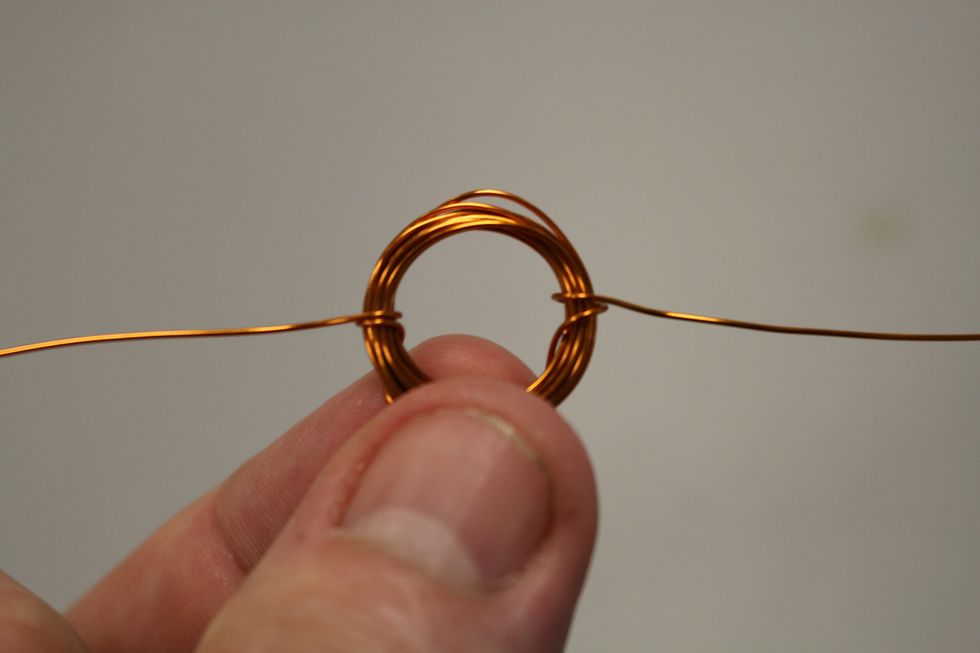

Carefully look at the coil and wrap the other loose end on the exact opposite side of the coil. They need to be centered opposite from each other so they balance each other.

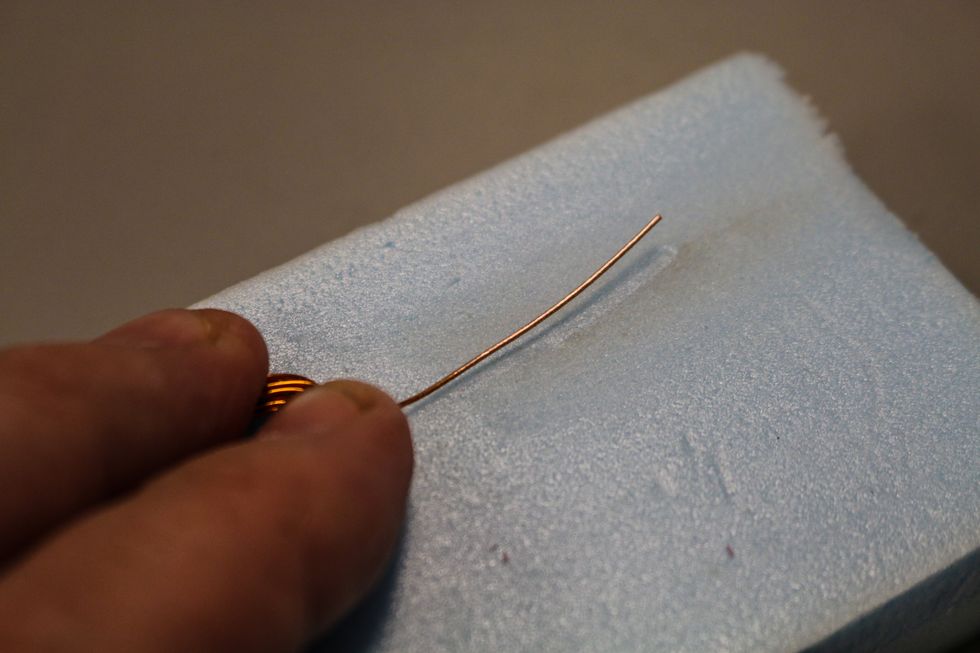

Try to straighten both sides.

Lay your coil flat and sand just one side (right) of one end of wire and then sand the other (left) wire end. Be sure the sanding happens only on one side of the two wire ends.

It should look shinier on the side you sand off the coating.

Back on the hook wires you are going to bend up their ends. These will be touching either side of your battery.

Both sides are bend up and you can see they are bent slightly in - so they press against the negative and positive ends of the battery.

Put the battery between them. Adjust/bend the wires to fit well then tape them down tightly against the battery.

Again - these will carry the current from the battery to the coil. Tape them down TIGHT!

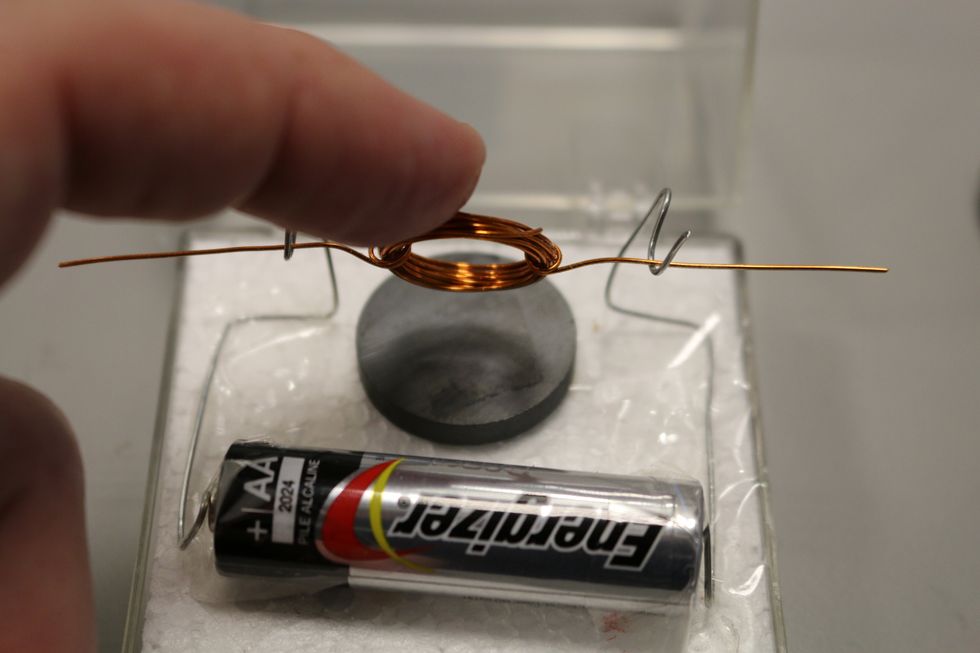

Now you can set your coil down in the hooks. Make adjustments so it is balanced and centered. Its crucial to be sure the two ends of the coil are centered.

Also make sure your coil does NOT touch the magnet - it has to be right over it so it can spin around. Give it a flick with your finger to spin it around...

If you've made all your connections carefully and tightly...it may start spinning around! If not check your battery connections and notice if its spinning in balance. Great job!

- 1.0 AA battery

- 18.0in magnet (coated) wire

- transparent tape

- 1.0 flat ceramic magnet

- 10.0in 18 gauge steel wire

- wire cutter

- small needle-nose pliers

- DIY bending jig if producing a lot

- small piece of 80-100 grit sandpaper

The Conversation (0)

Sign Up