STEPS

TOOLS

Recommended items.

Please ensure safety is observed through this process. Position forklift in an area away from work activities. Raise blades to approximately 4 feet for ease of inspection.

Remove key and secure lift. Place safety cones around raised blades.

Area of highest wear is near the 90 degree angle of the horizontal blade

Record the inspection date. If wear is between 7% and 8% notate and do quarterly inspections.

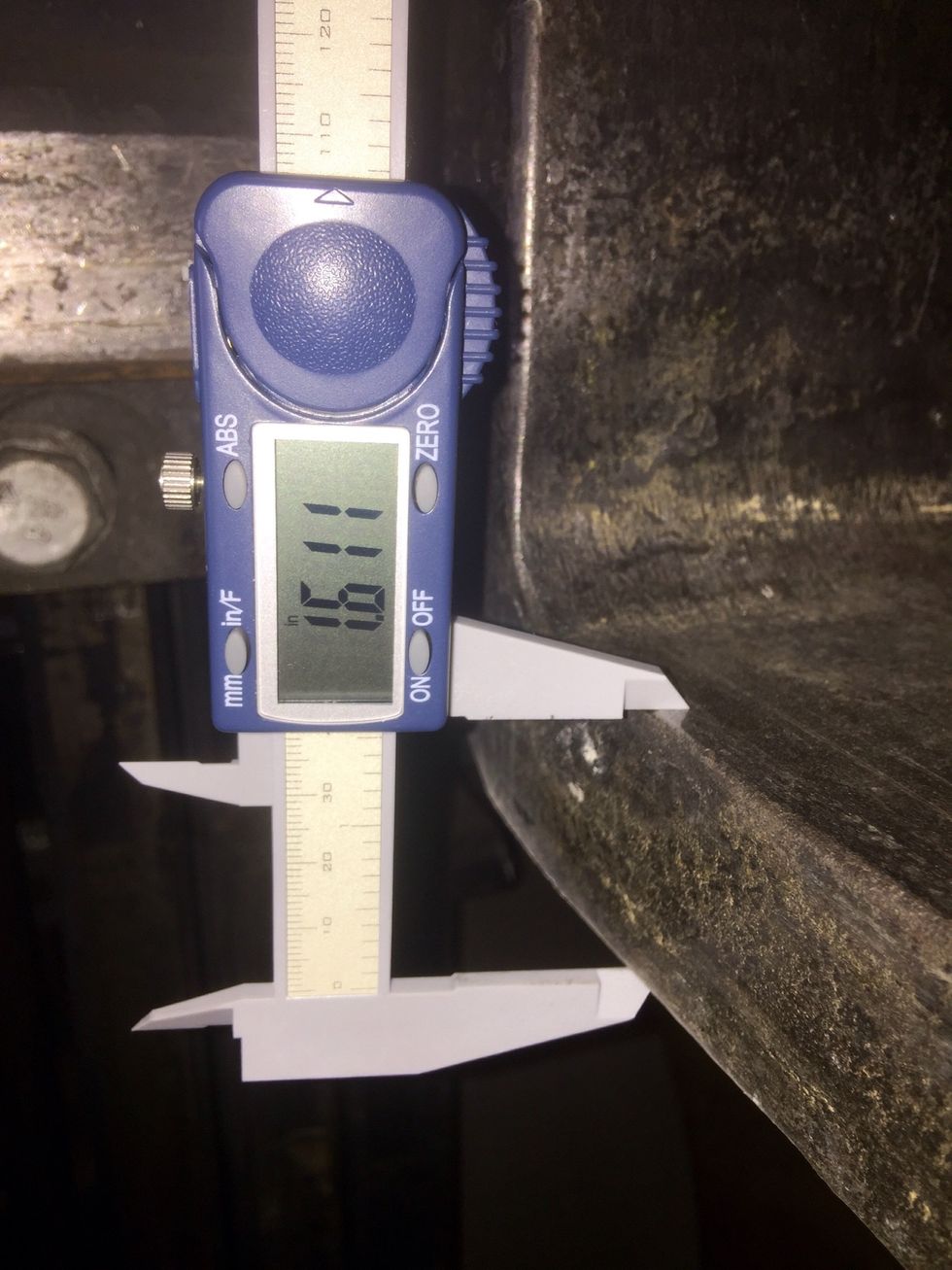

To get the baseline original fork diameter measure the upper veritical area of the blade. Ensure you zero out the caliper before measurement (see instructions for caliper use) This fork measures 1.60"

To calculate the minimum allowable diameter use the following formula ( original x .10 = amount to be subtracted from original diameter.

Now measure approximately 3" from 90 degree angle or visible highest wear area. These forks show no wear at 1.61". In this case 1.60 x .10 = .161. Subtract .161 from 1.60. Which is 1.43.

This is the generic fork tool used by some. This tool is not very accurate. A caliper is always recommended.

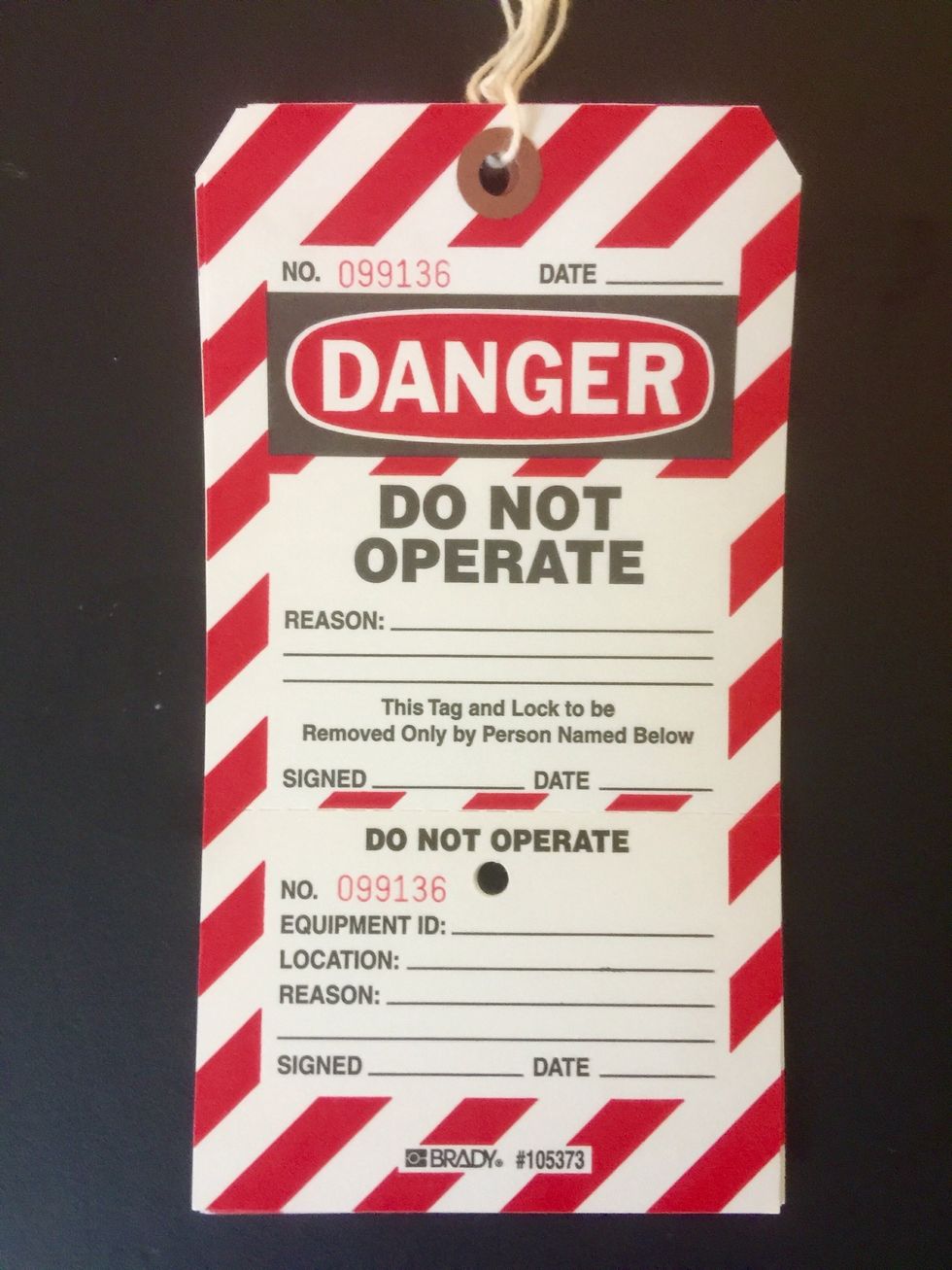

Finally if the forks are worn beyond 9% tag out unit and replace the forks.

- Automotive grade caliper

- Decal for inspection reference

- Flashlight

- Rag

- Out of Service tag

The Conversation (0)

Sign Up