How to change clutch plates on a royal enfield std 350

Change Clutch Plates on a Royal Enfield Std 350

178

STEPS

TOOLS

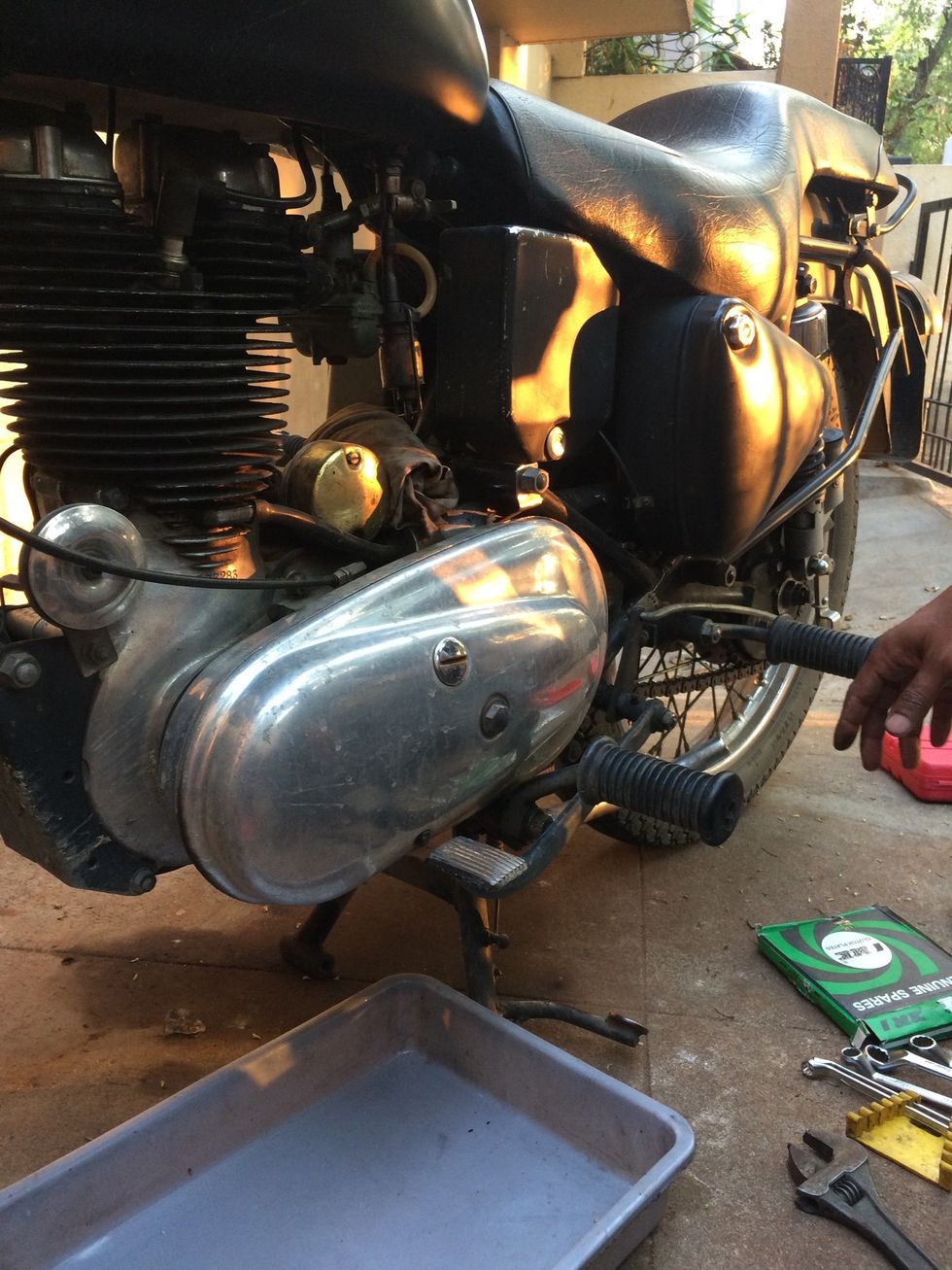

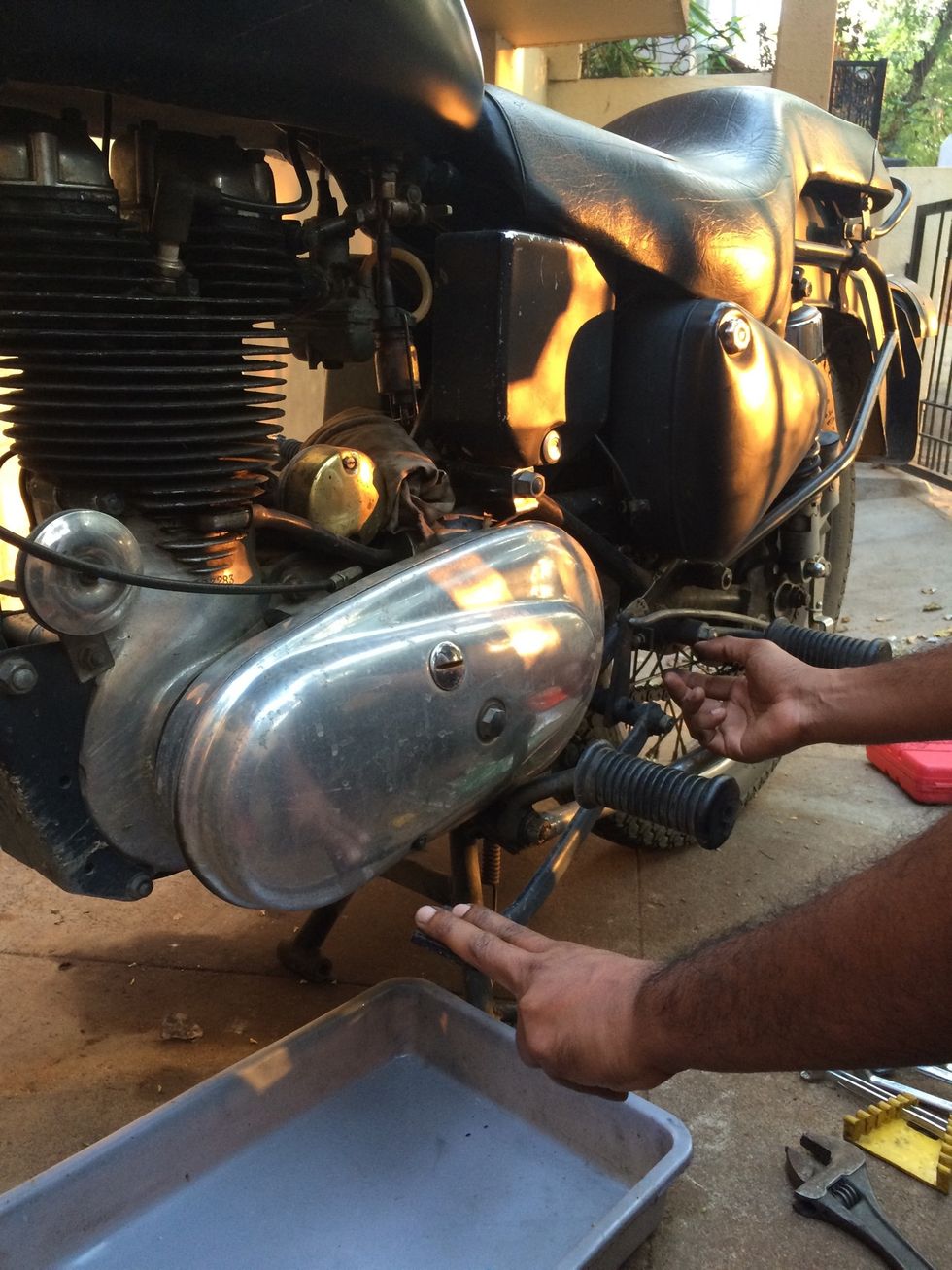

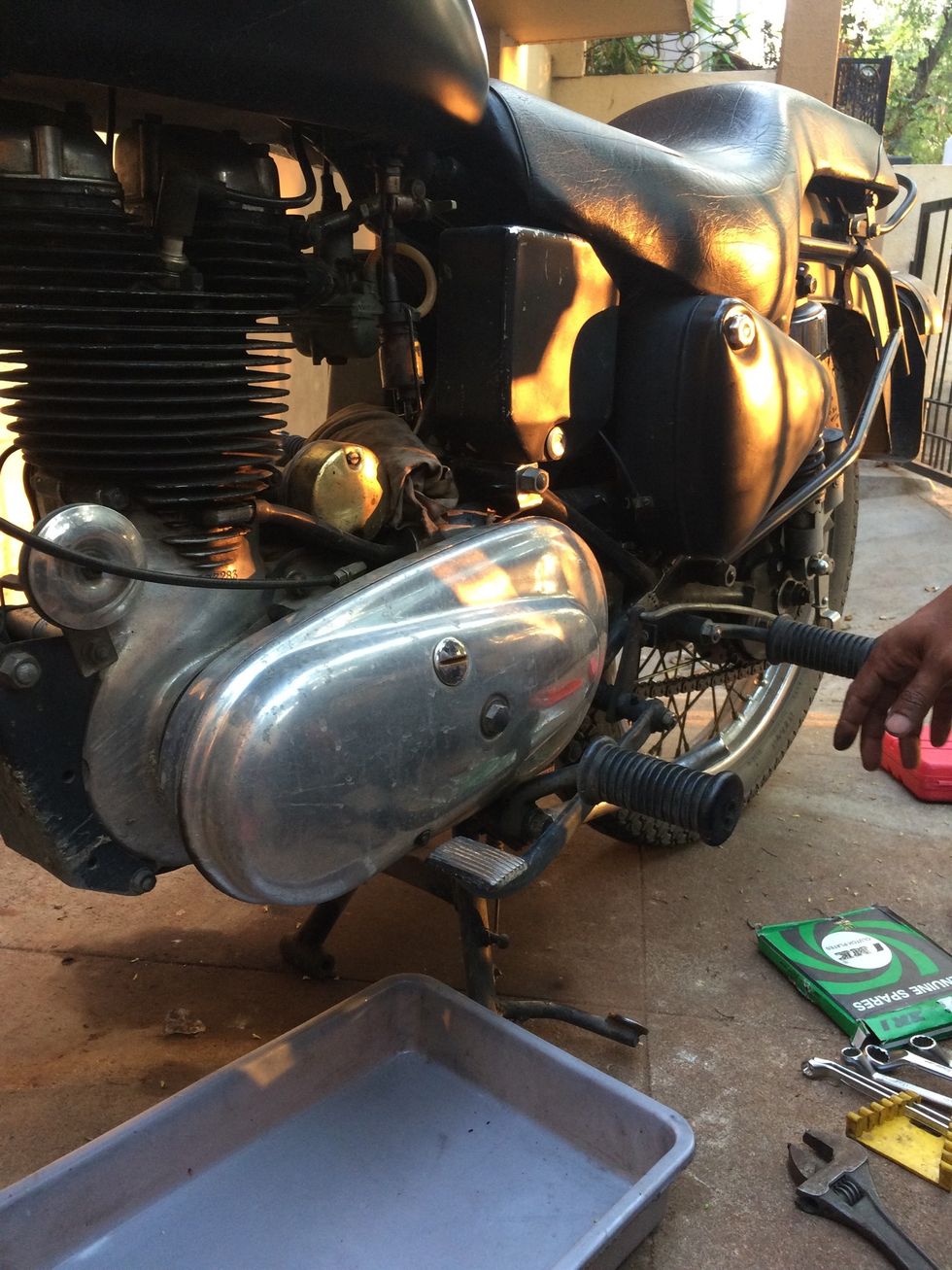

Place the motorcycle on centre stand with a tray to collect oil from the primary case.

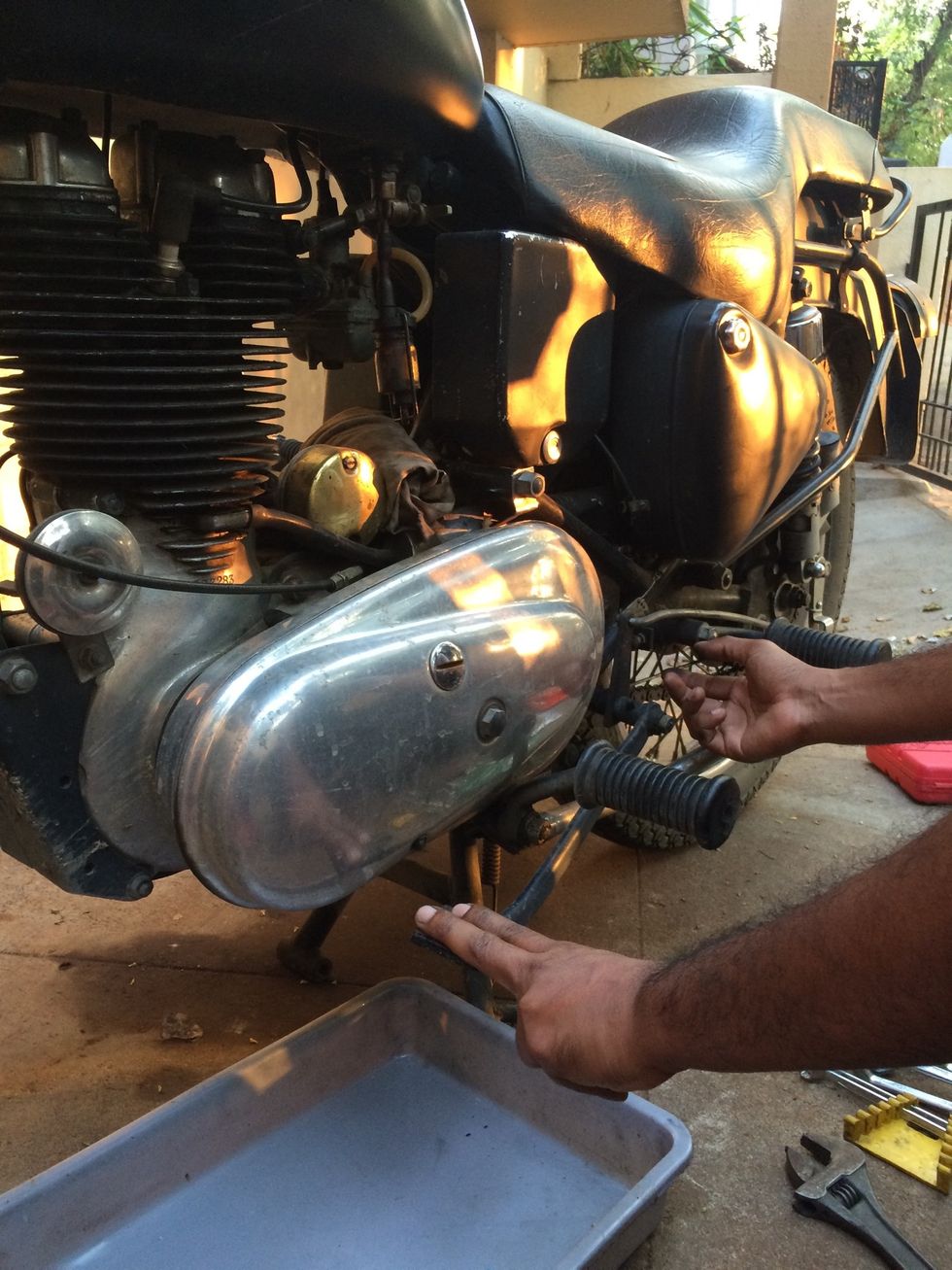

Press the brake lever

And extend the brake lever stopper bolt to hold the brake lever in the pressed state

This gives you more access to remove the primary cover

Remove or loosen the footrest nut

The footrest, if removed gives greater access for the job

Side prepped for job start

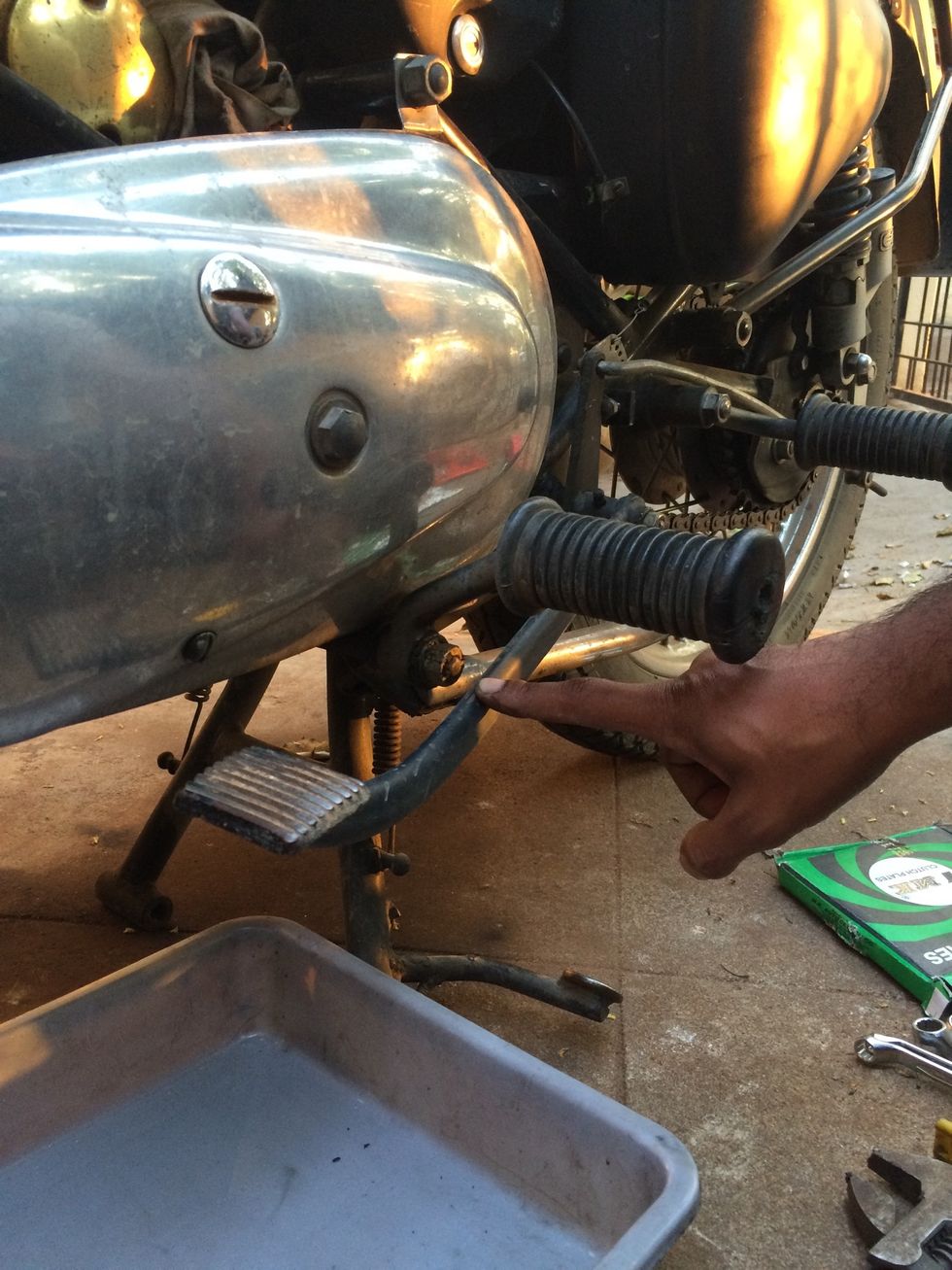

Use a 18mm wrench set and loosen the centre nut that holds the primary case.

Tap on the edges of the primary case until it loosens and oil starts dripping out

Slightly wedge the case out using a blunt screwdriver. Take care that you don't damage the O-ring

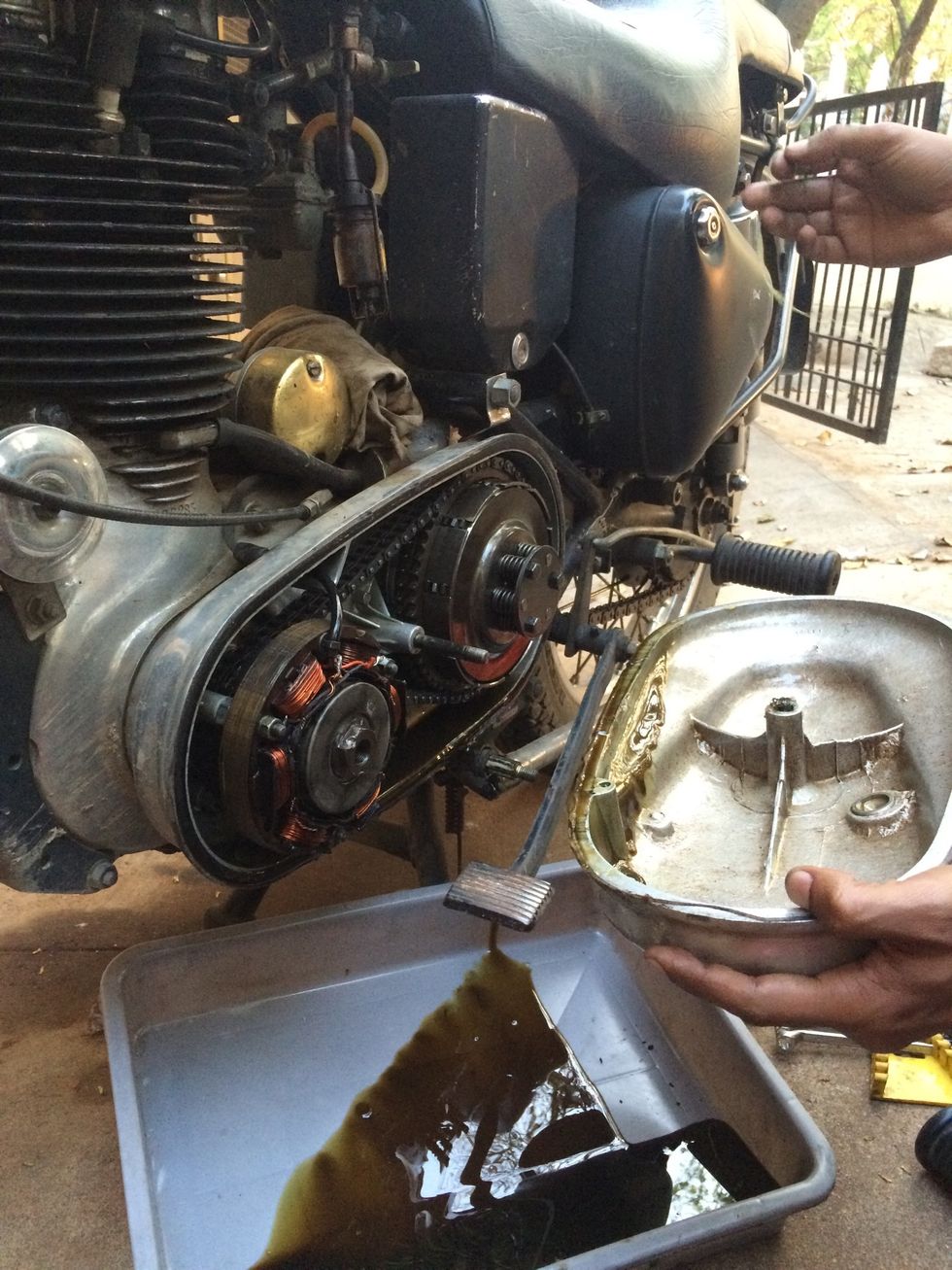

Case is removed and wait for oil to drain out

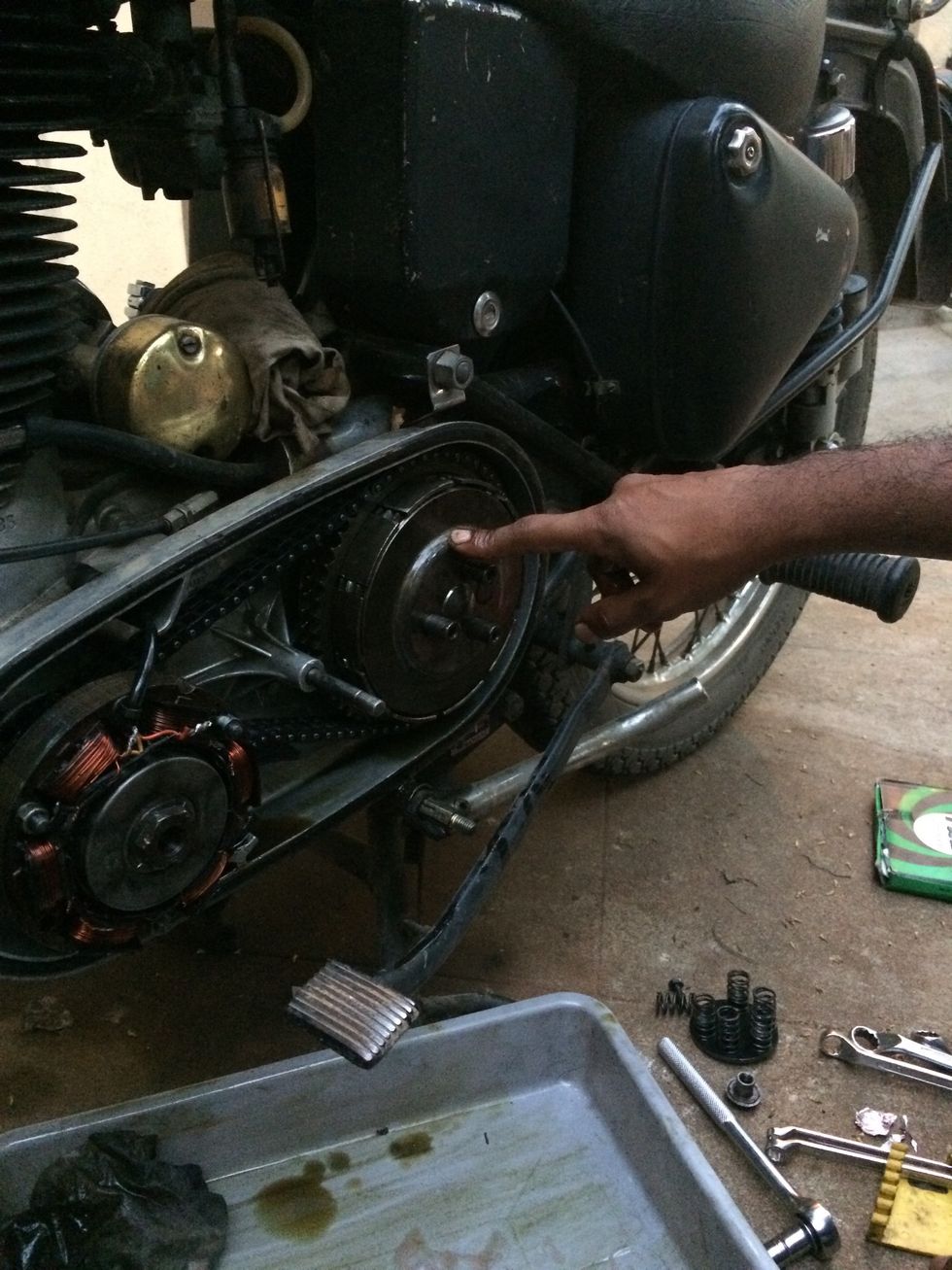

Engage first gear for aiding the clutch plate housing bolts removal

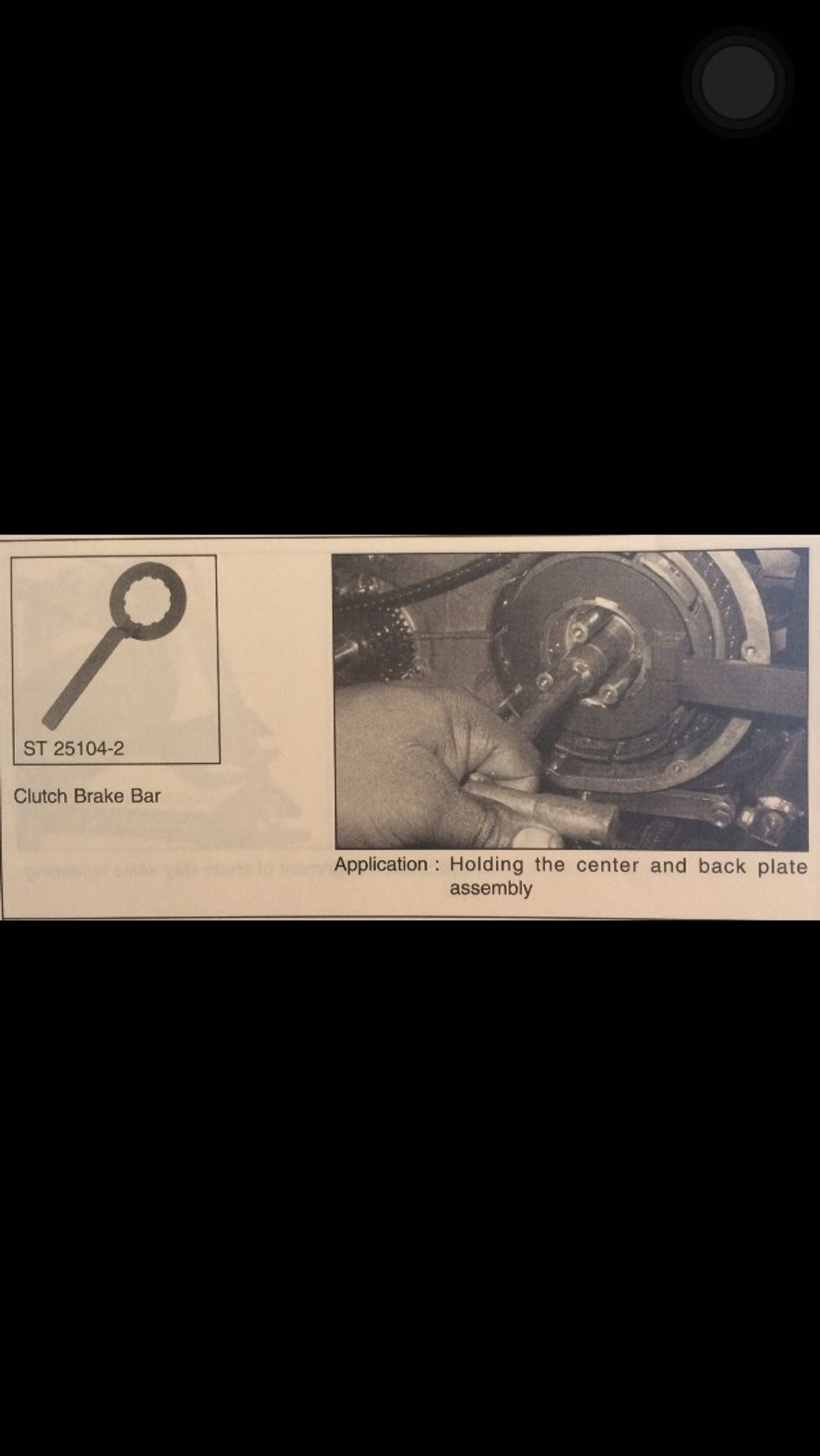

If you do have this tool, please use this rather than the tip in the next two steps

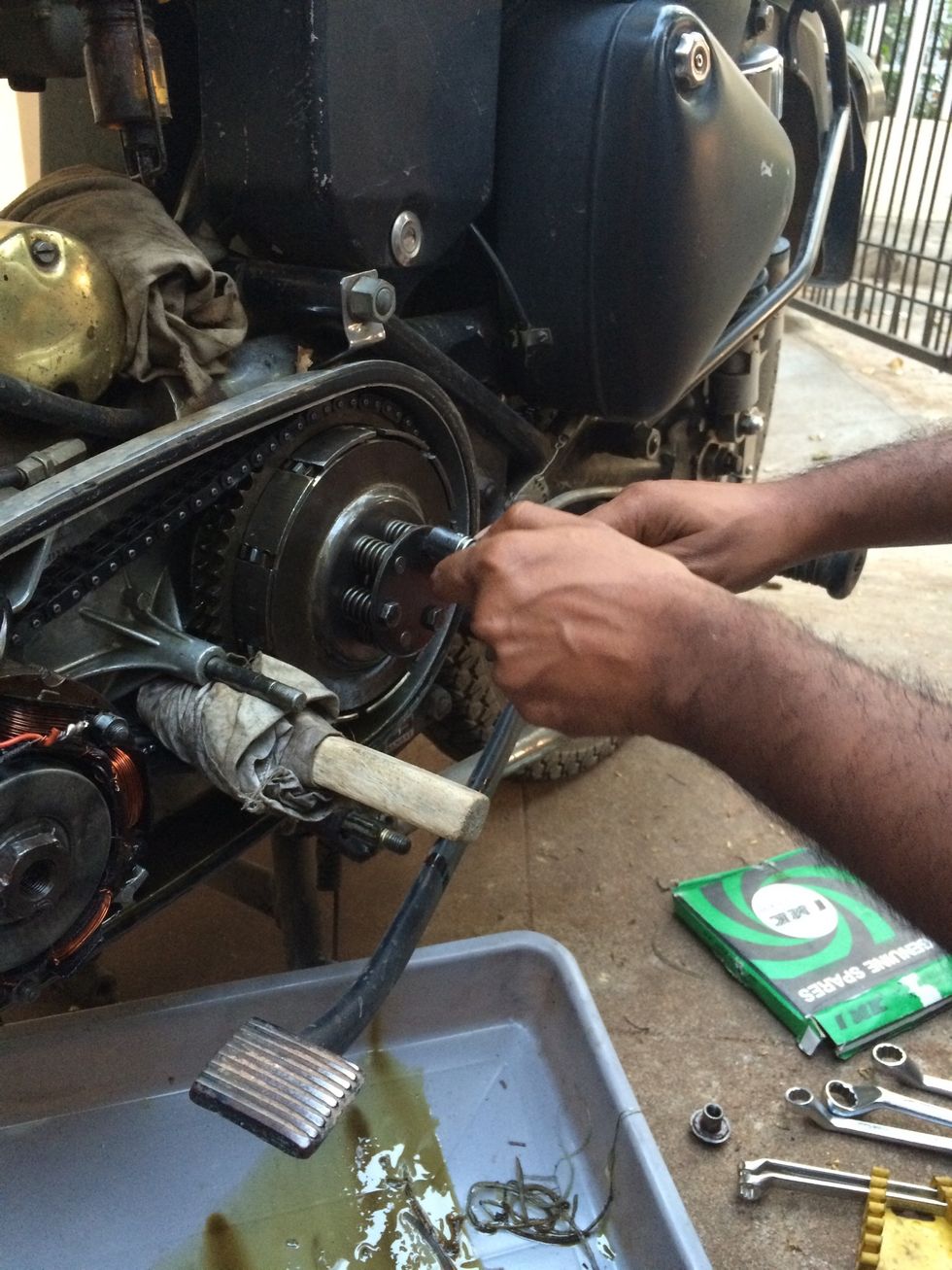

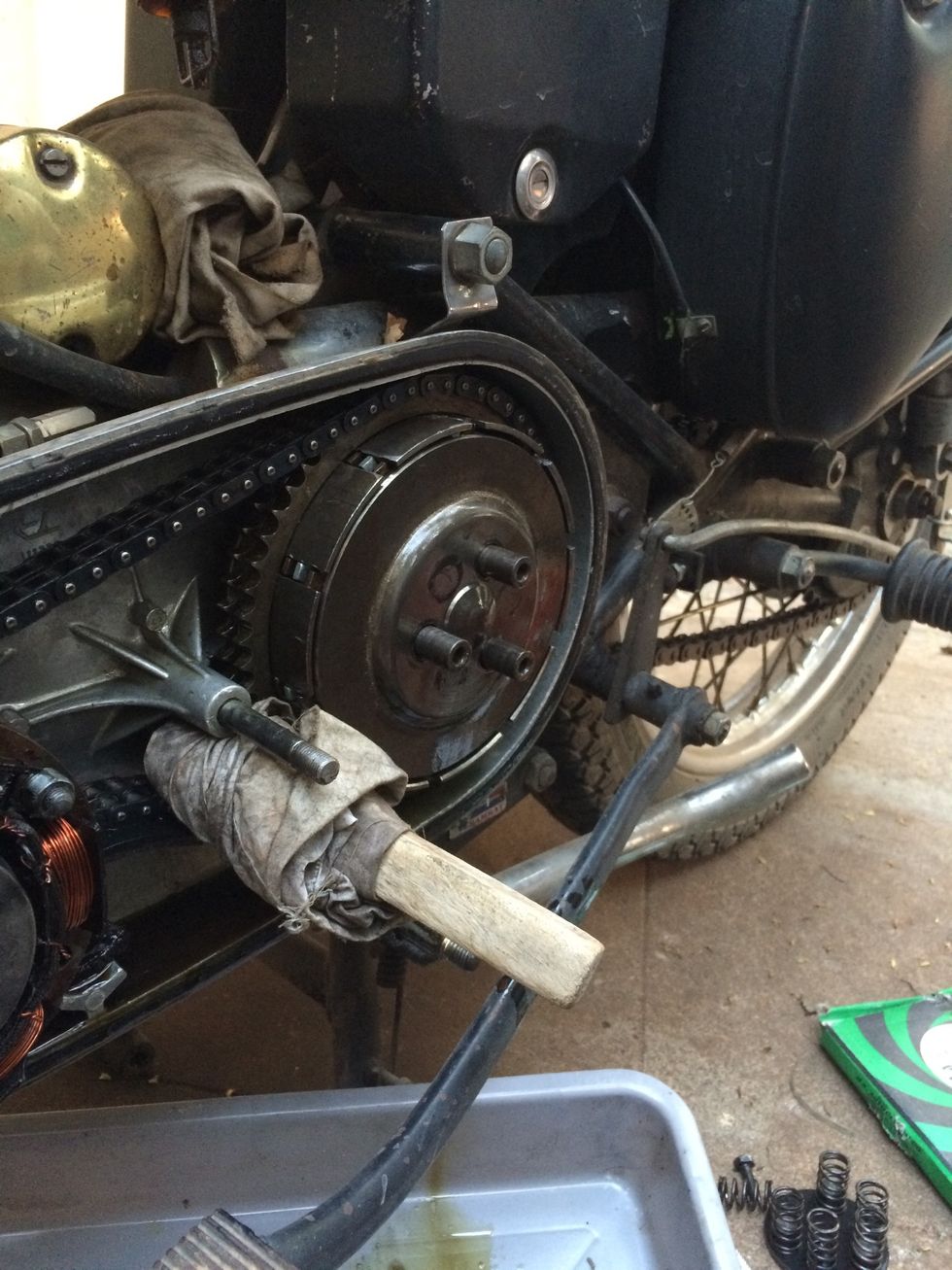

Wrap a cloth on a wooden piece and jab between the primary chain and sprocket

This helps lock the rotation while undoing the retaining bolts of the clutch plate housing

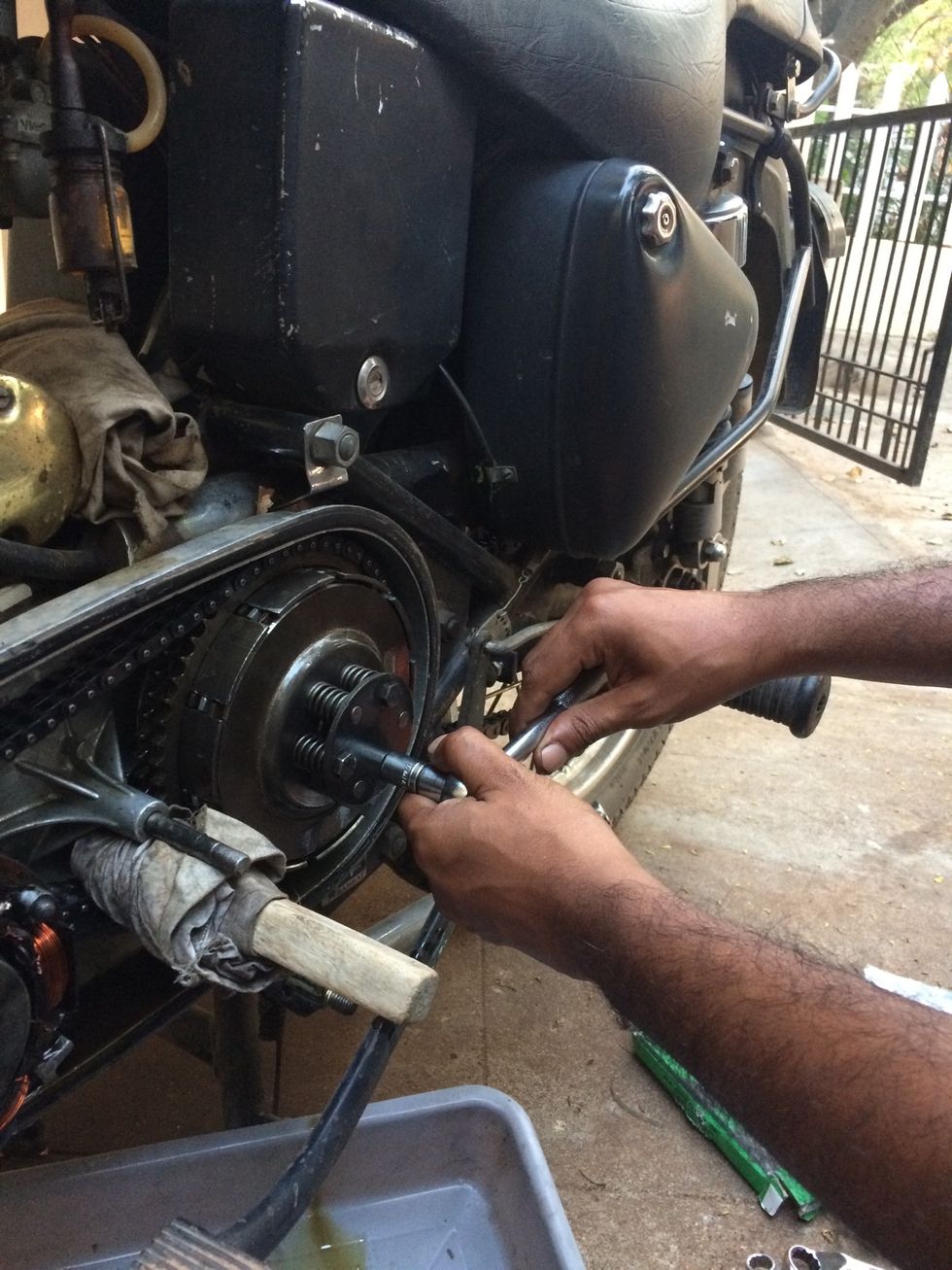

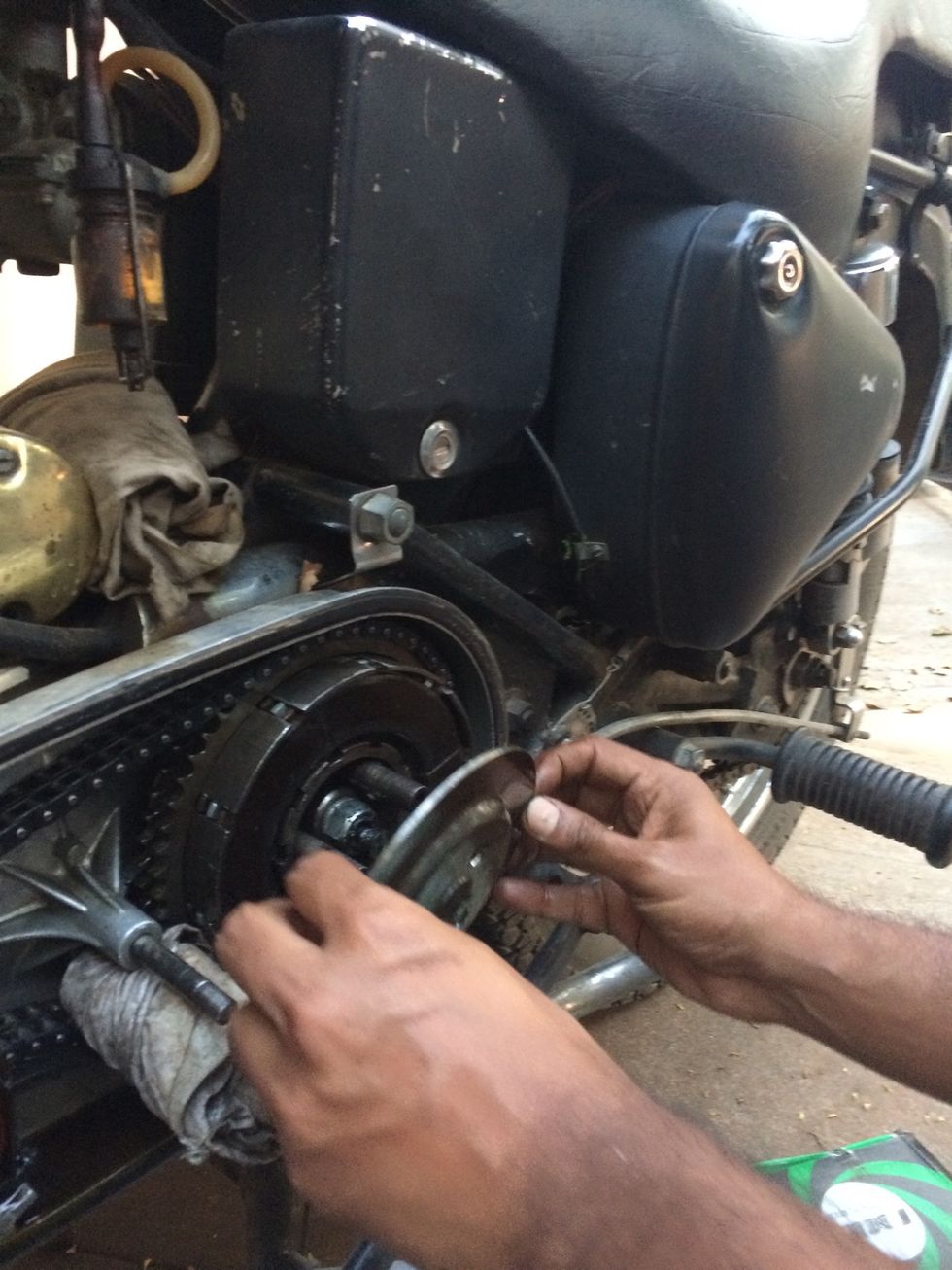

Loosen the three bolts alternatively. It is important not to undo one bolt at a time due to the spring tension

Loosen these three bolts alternatively

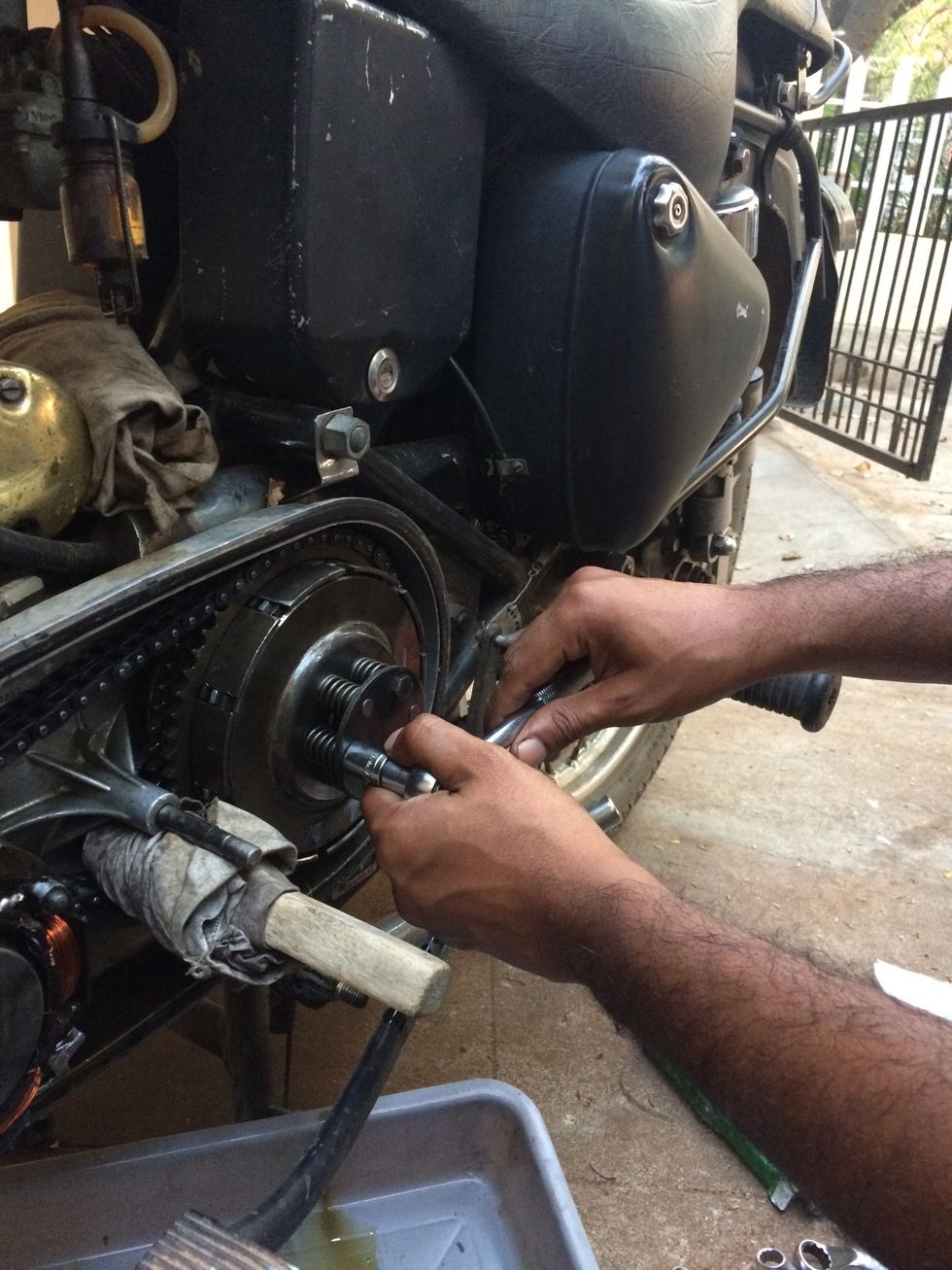

Same drill...

Remove the bolts and springs

Remove the remaining springs

Remove the plates and keep them aside in order of removal

One plate at a time to remember the sequence

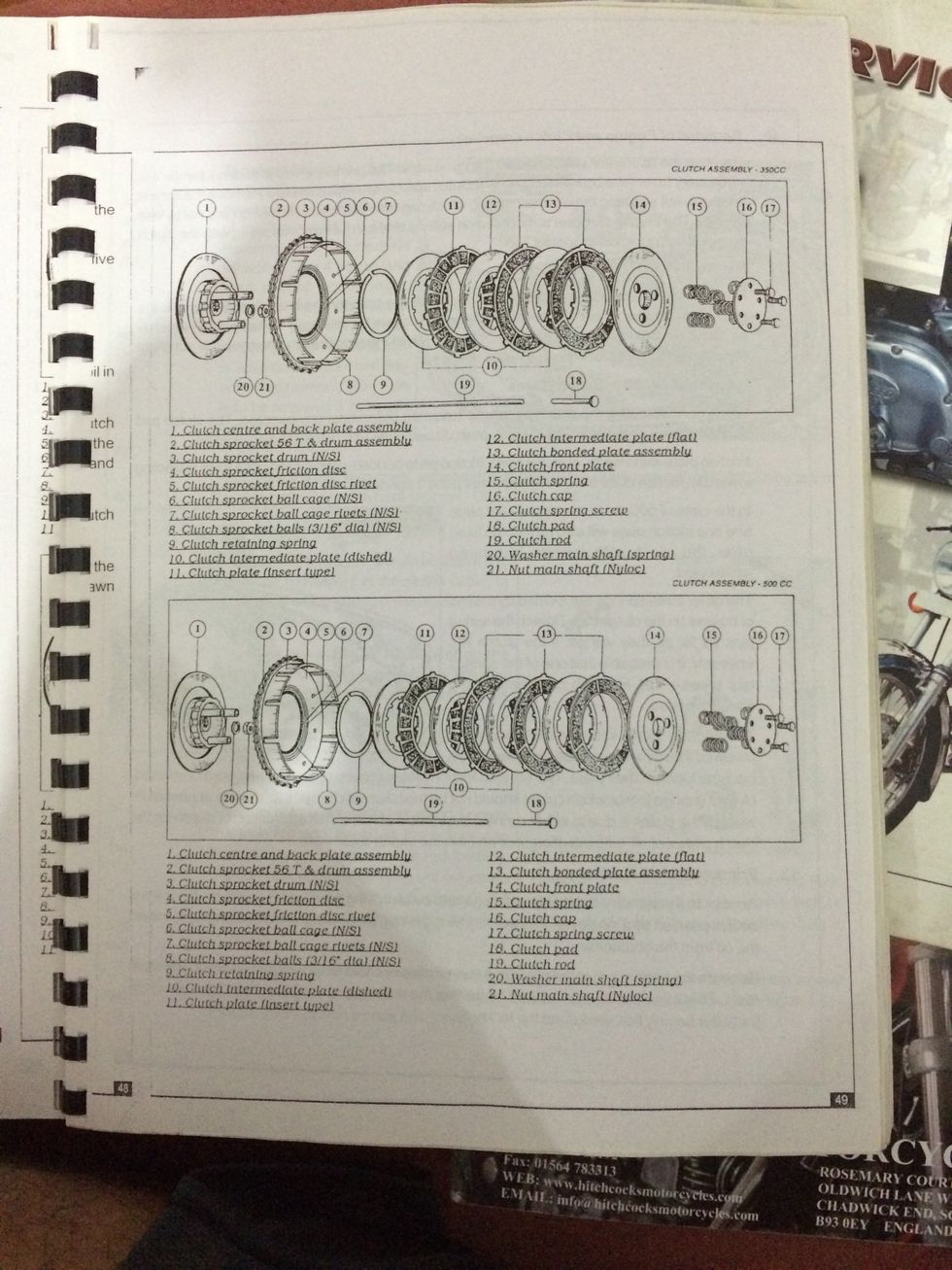

Order of plates

Use any brand 20W40 oil for refilling the primary case to set level

Use some 20W40 oil to wash the new friction plates

Cover the rubber padded plate as well with same 20W40 oil

Use the oil liberally to cover all the new plates

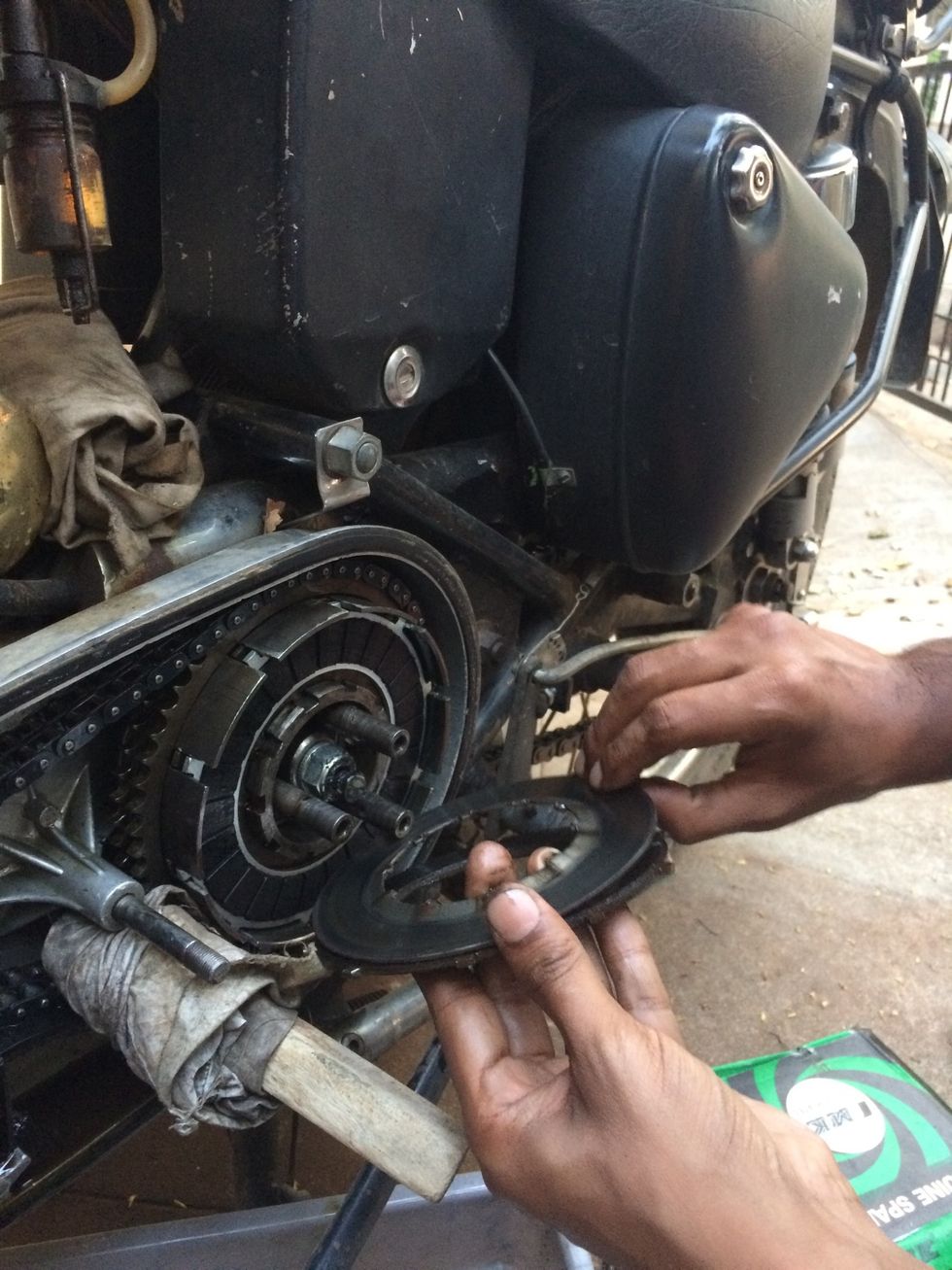

Reassemble them in the order of removal or refer to the diagram in step 23. Alternate friction plates and metal plates.

Wash once more with some 20W40 oil

Reassemble as per the photo, the inner most and outer most plates should have the bend edge towards you or facing outward of the engine core.

Place the outer cover back and tighten to specification

Remove the inspection cap

Remove the drain level screw

Pour in new oil until oil starts dripping from the bottom drain level screw hole

Once oil has dropped out, stop and tighten inspection cap and oil level drain screw

Fix the footrest back and tighten the nut

Press and readjust the stopper bolt for brake feel as per rider ergonomics

Inspect for leaks and tighten as per requirement. Clean the motorcycle and take it out for a test ride. Please wear protective gear including a helmet even for short test rides.

- 1.0part Friction plates

- 1/2l 20W40 oil

- 1.0l Tool set

- 1.0 Clutch Brake Bar - ST 25104-2 (Optional)

Soul Tech

Custom motorcycle builds, maintenance shop with optional traditional soul food from Kerala.

Melbourne

The Conversation (0)

Sign Up