STEPS

TOOLS

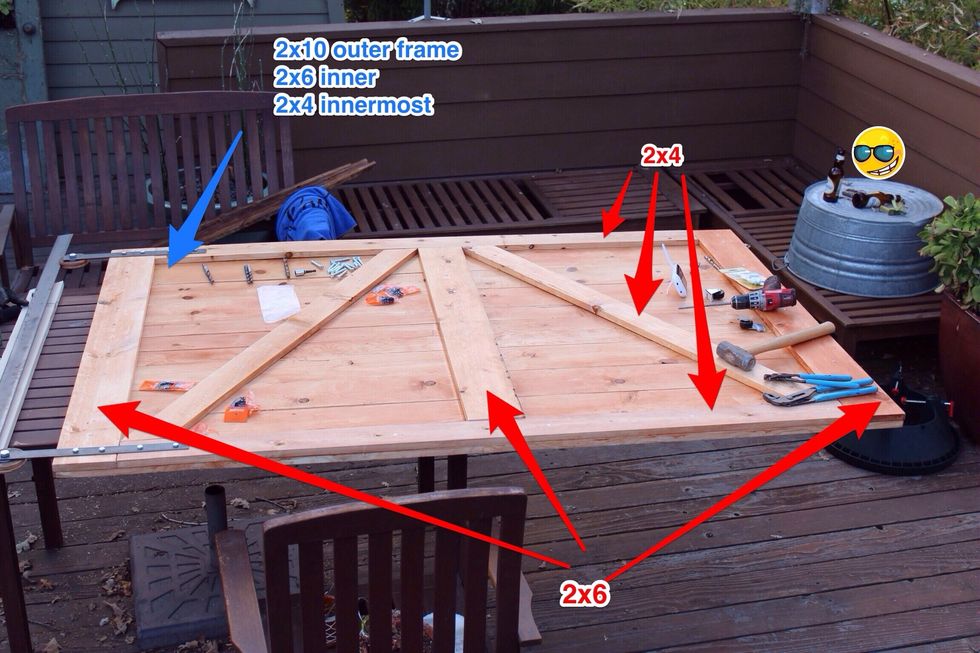

First build the barn door. Use inexpensive pine from Home Depot. The size will vary depending in your door opening. In my case the door was quite large.

Before putting it together sand each board and then coat each board with polyurethane stain. I recommend 2 coats. Lightly sand before each coat.

Here is the one I used. Looks great but takes a while for the smell to subside. I would recommend one a bit more safe for interiors and baby rooms. One advantage is that it is also a stain.

Fasten the left and right wheels to the door with 1inch wide steel. On the back side if the door use locking nuts to secure the steel . You can countersink the nuts in the back if you want them flush.

For the wheels use 1/2 inch wood. Use a 2 inch circular drill bit to cut two 4 inch wheels for each side of the door. Cut the center out for the bearings and bolt.

Join the 3 circles you cut together to allow the track to slide between them. The smaller circle will be sandwiched between them.

Tools! 3 circular drill bits. 1 inch thick board for the wood. Also one example of a wheel that is cut out.

Place 3 wheels at the bottom of the door. I took the smallest caster I could find from Home Depot and cut the tops so I could sink them into the door.

This is my sloppy cut of the wheel. I did this so that the door would not be any taller and throw other things off.

To create the handles use 1.5 inch steal. Drill 2 holes in the steal and the door, and placed a washer with a 1 inch steel pipe to extend the handle off the door. Secure with lock nuts on the rear.

For the track use a piece of black steel that was 4in thick. Place support screws through to the wall evenly spaced and connect to studs.

Make sure you use a stud finder to assure your track is safely secured to the wall. This one is about 15 bucks at Home Depot.

At each end of your track you must have a stop. There is many ways to do this, but I choose to bend the steel up.

Close up of the bolt and steel connecting the track to the wall. Be sure to allow the screw to be flush to allow the door to pass. Also use washers to distribute weight of connections.

4 inch bolt with large top should be used for the end of each of the track. The thinner screw with a flush head should be used throughout the middle, evenly spaced. Attach to studs.

Example of hollow steel tube. This is the 1/4 inch thinner tube, which can be found at Home Depot. The bolt will sit inside this with a washer where it attaches to the wall.

When placing the support bolts on your main track, be sure to allow enough room for the wheel to pass and not hit the steel connected to the wall. Also consider the screw on the front of track.

Close up of handle with bolt, washer and hollow steel support.

Using a closet door wheel I fashioned a track to keep the door straight when opening and closing.

This is a picture before mangling it.

On the opposite side of the wheel I screwed a piece of bent 2inch steel to act as the other side of the track.

To keep the door always on its track cut a piece of left over steel to act as a guard at the top of the door. There should be one on ends of the door.

Viola! Your own barn door, just heavy enough to keep the little one out, but...

Easy enough for mom to open.

Lock nut should be used for all bolts.

This is my cheap cheap flea market chop saw fitted with metal blade cutter. Be warned wear eye protection, the sparks will fly.

Another flea market find. I used this to smooth all edges of cut metal.

- Wood for door - pine

- 1.5 inch wood screws

- Polyurethane stain

- Three 1 inch casters

- 4 inch black steel track - length may vary

- 2 inch black steel track

- Flat 4 inch screws - amount will vary

- 2 1/4 anchor bolts

- 1/4 inch steel tube

- 1/2 inch steel tube

- Washers for all larger bolts and screws

- 1/2 inch wood piece- for wheels

- 1/4 inch bolt for wheel x 2 length 4 inches

- Lock nuts for all bolts

- Metal drill bits

- Metal circular saw blade

- Drill

- Chop saw

- Hand saw

- Metal file to smooth out edges of cut metal

- Paint brush

- 4 inch circular drill bit

- 2 inch circular drill bit

- 2 inch bearing

John-Carlos Lozano

Creative director and principal @ Sweetrush, a multimedia interactive training and education company. Passionate about learning and curious about everything.

Santa Rosa, California

The Conversation (0)

Sign Up